Email: anwenqq2690502116@gmail.com

Application of Radio Frequency Identification Technology in Laminated Wooden Doors

Laminated wooden door production process characteristics and management requirements, use RFID electronic tags to solve production, warehousing, logistics, installation and after-sales problems.

Abstract: According to the production process characteristics and management requirements of laminated wooden doors, radio frequency identification (RFID) electronic tags are used as the main information carrier in production, warehousing, logistics, installation and after-sales, and a vertical distributed system based on RFID technology is constructed. Wooden door manufacturing information acquisition and processing model structure, and the implementation process of each functional module.

The application results prove that this information collection and processing model can replace the traditional two-dimensional code system, and solve the problems in the traditional production process that the two-dimensional code is easy to be polluted, repeated codes, data can be read but not written, and data information is missing. The production of wooden doors The efficiency has been increased from 1.5 min/window to 1.0 min/window, and the comprehensive management time has been shortened from 10-15 minutes/window to 5 minutes/window, realizing the full integration of wooden door processing, warehousing, logistics, installation and maintenance. process management.

Key words: laminated wooden door production, RFID technology, integrated management, IoT RFID technology

As a subdivision of the traditional home furnishing industry, China's wooden door industry is constantly expanding its market size. With the deepening of China's digital and intelligent transformation, it is ushering in a major opportunity for transformation, upgrading, and innovation and development. The current production mode of Chinese wooden doors is characterized by custom-made production, the production process and product structure are relatively complex, there are many types of raw materials and parts, and the product has high added value. Its manufacturing level represents the manufacturing level of high-end wood products in China to a certain extent.

Application of radio frequency identification technology in information integrated production mode of laminated wooden doors

At present, the production processes of different wooden door enterprises in China are slightly different, and the equipment configuration is relatively flexible. Product quality and production efficiency largely depend on the technical level of workers and automated stand-alone equipment, and the production cycle is relatively long.

Most enterprises use barcode or two-dimensional code as the information carrier in the process of parts processing and circulation, mainly relying on the factory MES system, relying on the network for communication, the equipment requirements are also high, and the information storage capacity is small, only one-way reading function , the surface is often damaged and the processing information cannot be read, which makes it difficult to track the production progress in the management link, the material and production loss statistics are not timely and accurate, the warehouse management is chaotic, and "wrong orders" often appear in the logistics and installation links. Phenomenon, causing unnecessary waste of time and material costs.

Radio Frequency Identification (RFID) technology is a non-contact automatic identification technology, the principle of which is non-contact data communication between the reader and the tag to automatically identify the target object and obtain relevant data, the recognition process does not require manual intervention, and has strong applicability to different industrial environments.

RFID has the advantages of large storage capacity, long reading distance, multiple identification targets, and data encryption. It has been widely used in commercial department store sales, warehousing logistics, transportation, and automobile manufacturing.

At present, RFID has been used in some foreign countries in the field of furniture and wood products. For example, Northway Industries, a well-known wooden furniture and office supplies customizer in the United States, uses RFID systems to track the manufacturing process of products; Source UHF RFID technology was integrated into the Valede Cambra factory to improve production efficiency and save management costs; Thomasville Furniture Industries, a famous American furniture manufacturer, used RFID network and infrastructure to provide product traceability for large retail customers.

At present, there are few reports on the application of RFID technology in the wooden door manufacturing industry at home and abroad. In view of this, according to the production characteristics of laminated wooden doors and product management requirements, this study takes RFID as the main carrier of laminated wooden door manufacturing and management information, studies the application mode of RFID technology in wooden door production lines, and constructs a laminated wooden door based on RFID technology. The application model of information collection and processing of wooden door manufacturing realizes the information collection and real-time tracking and monitoring of the whole process of wooden door processing, transportation, installation and after-sales.

1. RFID system composition and working principle

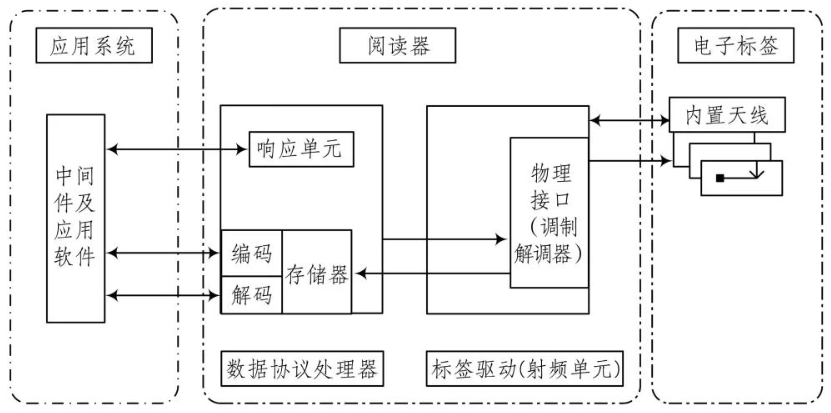

The RFID system consists of three parts, including: RFID electronic tag (TAG, transponder), reader and application system.

1) The electronic label is packaged in the door leaf and contains a dedicated chip and tag antenna. The dedicated chip is the main data carrier for radio frequency identification. Data in a certain format is stored in the dedicated chip as the read information of the product to be identified. The built-in antenna is mainly used for Communicate with the radio frequency unit in the reader.

2) The reader is a device for reading or reading and writing electronic tag information. Its main function is to control the internal radio frequency unit to transmit reading signals to the electronic tag, receive the response of the tag, and send the product identification data together with other relevant information in the tag to the host.

This research mainly uses the split fixed reader to read the processing data information at the front end of the production line equipment, and uses the mobile handheld reader to manage the product process in the storage, transportation and assembly of wooden doors.

3) The application system is mainly composed of middleware and application software. The middleware can write and read data to the tag through the reader, and connect the reader and application software. The application software mainly includes enterprise production and management information software, such as enterprise resource Management (system applications and products, APS), enterprise resource planning (enterprise resource planning, ERP) and wood processing computer-aided design/manufacturing (wood CAD/CAM, WCC), etc. The specific composition is shown in Figure 1.

Figure 1 Composition of RFID system - IOT Application Example

The working principle of the system is that after the door leaf encapsulated with the electronic label enters the antenna magnetic field, it receives the carrier signal sent by the front-end (or mobile terminal) reader of the processing equipment, obtains the required energy through the induced current, and sends the signal stored in the dedicated chip. Wooden door product information, or actively send a certain frequency signal. The reader reads and decodes the information, and transmits radio wave energy of a specific frequency through the antenna transmitter to drive the transponder circuit to send internal data to the central information system for relevant analysis. Finally, these data are sent to the application program for corresponding processing.

2. Laminated wooden door production process and RFID application requirements analysis

2.1 Laminated wooden door production process

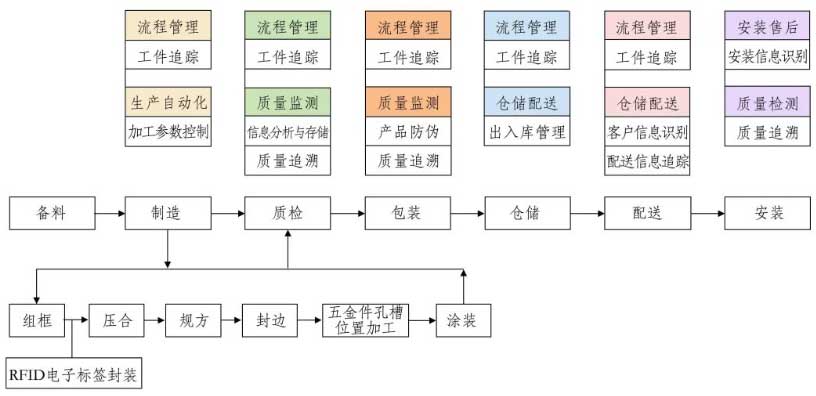

The laminated wooden door is a wooden door made of veneer, decorative paper or other decorative materials, and the door frame is filled with door core materials. The wooden door is made of multi-layer materials through lamination. High cost performance is more and more favored by consumers. From raw material processing to finished product installation, laminated wooden doors need to go through raw material preparation, manufacturing, quality inspection, packaging, storage, distribution and installation, as shown in Figure 2.

Figure 2 Production and distribution links of laminated wooden doors

Compared with panel furniture, the laminated wooden door is integrated after the panel and the frame are combined, and the subsequent processing object is a whole, that is, one or very few RFID electronic tags are needed to complete information collection. In addition, the shape of the laminated wooden door is fixed, and only the size is different according to the customization requirements. It occupies a small space, and because there is a certain space inside the door core, it is convenient for the packaging of RFID electronic tags. Therefore, in the manufacturing process of laminated wooden doors, it is generally chosen to place the RFID electronic tag inside the door leaf after the frame is assembled and before the panel is pressed.

2.2 Analysis of RFID Application Requirements

There are many manufacturing processes of wooden doors, and a lot of equipment is involved. Although many equipments in the existing wooden door production line can be automatically processed by recognizing barcodes, they are mainly concentrated in the four-sided sawing of the door leaf, edge sealing, opening hardware hole slots and other links. The digital management of the whole process has not been realized, and the automatic information collection of the whole process is missing, making online management and control difficult.

Once a product quality or equipment failure problem occurs, it is difficult to solve it quickly, cannot guarantee product quality, and affects production management efficiency. The application requirements of RFID in each link of wooden door production and circulation are analyzed as follows.

1) Realize the transparent management of production. By using RFID electronic tags as the information carrier, it is possible to obtain and write key information about the status of products in the stages of processing, transportation, installation and after-sales in real time and efficiently, and timely grasp the working condition information in the relevant stages of products in progress, so as to judge for managers Provide sufficient data support for decision-making.

RFID TAGS

2) Realize the lean management of production. The use of RFID technology to realize real-time tracking of the production process can enable enterprises to know the production status in a timely manner, and flexibly adjust production capacity according to order requirements and process links, so as to maximize the balance of productivity. This method can make workshop management more lean, production more flexible, and help enterprises achieve more efficient production management.

3) Realize the intelligent management of the production process. Through RFID technology, the order information of different batches, specifications, sizes, and colors of wooden doors can be identified and saved, and the processing sequence of processing equipment such as door leaf pressing, four-side sawing, and hardware hole slot processing can be controlled to improve the intelligent manufacturing of the production process. level.

4) Realize online control of product quality. Aiming at the problems of four-sided sawing, edge sealing, and hardware hole groove processing in the current wooden door production process, edge chipping, burnt, exposed seams, scratches, pits, hardware hole groove dislocation, and type processing confusion are easy to occur. The readable and writable characteristics of RFID electronic tags, with the help of machine vision technology, automatically writes unqualified information into the RFID electronic tags inside the wooden door, realizes the automatic separation of unqualified products in the later stage, and can trace product quality in time to improve product quality and production efficiency.

5) Realize the information management of warehousing and logistics. Utilizing the long-distance identification function of RFID electronic tags can improve the information management level of the warehouse, quickly identify the order information and storage location of the product, simplify the inspection and acceptance procedures for entering and leaving the warehouse, and save the inspection, recording, and processing required by traditional manual operations. Inventory and other links. In the distribution process, RFID tag technology is adopted, which can reduce the loss caused by misplaced goods and shipping errors, and improve service quality.

6) To achieve the accuracy of distribution and installation. Utilizing the reading and writing function of RFID electronic tags can ensure the accuracy of the customized wooden doors in the distribution and installation position, avoiding the phenomenon of "wrong order" and causing unnecessary waste of time and material costs.

3. RFID application mode on laminated wooden door manufacturing production line

3.1 Vertical Distributed Model System Construction

According to the characteristics of the laminated wooden door production process and product management requirements, the laminated wooden door manufacturing model framework based on RFID technology is studied. It adopts a vertical distribution structure and mainly consists of three parts: the control layer, the execution layer and the business layer, as shown in Figure 4. Show.

Fig.4 Framework of vertically distributed wooden door production model based on RFID technology

1) Control layer: refers to the workshop control network composed of split fixed readers and related sensors installed on equipment such as panel compounding, four-side sawing, edge banding, and hardware hole processing, and completes on-site device control through computers , including programmable logic controller (PLC), computer numerical control machine tool (computer numerical control, CNC), distributed numerical control (distributed numerical control, DNC) and distributed control system (distributed control system, DCS) and other equipment.

The main function is to automatically collect and interconnect product data information through the RFID electronic tags preset in the wooden door, to realize real-time interaction and information integration of data between equipment information and software systems at different stations and different processes, and to improve production. efficiency and management level.

2) Execution layer: refers to the manufacturing execution system (manufacturing execution system, MES) management and tracking of materials, production, quality, equipment, batches of key parts and other information in the manufacturing process.

Different functional modules can be set to complete the detailed decomposition of manufacturing management information at the business layer, and on-site management of each device at the control layer to ensure the continuous and normal production process. At the same time, the sensitivity of on-site management can be improved by means of material inventory monitoring, equipment status monitoring, production progress monitoring, and quality status monitoring, and the analyzed and processed data information can be transmitted to enterprise managers in real time for production decisions.

3) Business layer: mainly refers to the basic business operating system required by the enterprise during normal production and marketing, including production management control, enterprise resource planning, product quality control, warehousing and distribution, installation and after-sales and other application systems. The operation of these application systems can improve the management efficiency of enterprises and improve the accuracy of management decisions.

Supply RFID Label High Frequency RFID Chip Sticker - RF Chip - China Electronic Label Manufacturer

3.2 Functional module composition

According to the requirements of wooden door manufacturing and logistics management, the vertically distributed laminated wooden door manufacturing model framework based on RFID technology includes five functional modules: process management module, production automation module, product quality monitoring module, warehousing and distribution module, and installation after-sales module. These modules can provide relevant data information according to different needs, so as to realize the efficient management and optimized operation of the wooden door manufacturing production line.