Email: anwenqq2690502116@gmail.com

RFID Technology Applied to Digital Factory - Wanquan Smart IOT Company

In manufacturing plants, daily management is more focused on issues such as product management, quality management, warehouse management, mobile asset management, on-site personnel management, and fleet management.

The collection of most factory production line information usually adopts manual collection and manual input, which is far from accurate and has a large error rate. The production data in the system cannot be updated in real time, and the lag is serious, which is not conducive to the smooth progress of production and restricts the further improvement of production capacity.

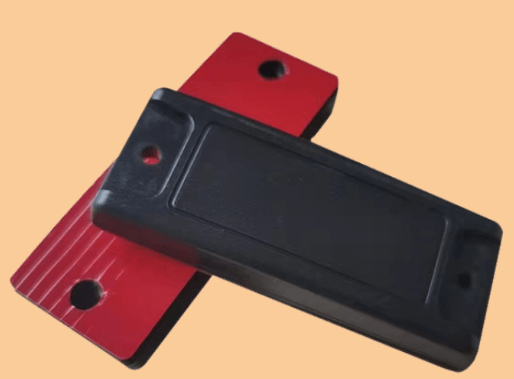

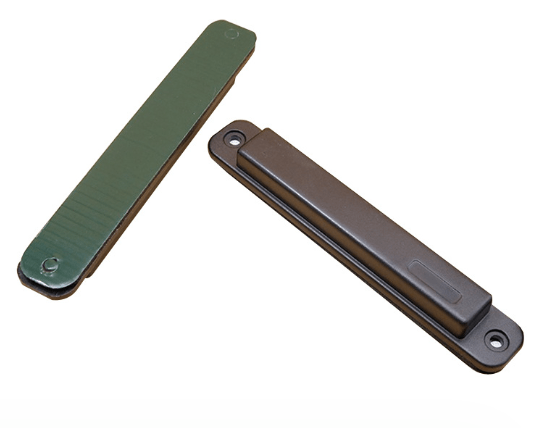

RFID anti-metal tag ABS UHF electronic radio frequency tag

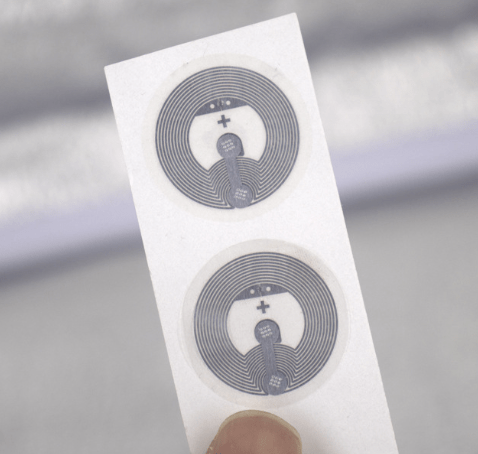

Based on the RFID technology management system, RFID radio frequency identification technology is applied in the production line, transfer and temporary storage warehouses, and reusable RFID electronic tags are applied. Each tag has a unique ID number and a readable and writable data area. The information is written into the RFID electronic tag, and RFID readers are installed at the production line off-line station and the warehouse entrance and exit, and the automatic batch identification of product label information is uploaded to the management system. Semi-finished products are tracked and managed in the whole process from off-line to warehouse transfer, temporary storage, and on-line production.

RFID factory production line management

Deploy RFID readers and antennas at each station. When the goods with RFID tags enter the identification range of RFID readers, the data information stored in the electronic tags on the products will be automatically identified; and the background management system will be uploaded in real time to manage The system then lists the package number, batch and other information of the goods according to the product production information, and displays them on the display screen to prompt the production workers to perform correct operations.

The application of RFID technology in the factory production line has advantages that other technologies cannot match. It can automatically read data without contact and can withstand harsh working environments, which ensures that its advantages are flexible configuration, fast response speed, and requirements for system communication. Low, read the information of RFID tags, collect information such as product location, production level, serial number, etc. Realize the flexible management of the production line, the visual management of the production line, the information management of the production line, the data management of the production line and the automatic management of the production line.

Based on RFID automated production line application fields: tobacco automation management, automobile manufacturing, food and pharmaceuticals, electronic information, clothing production lines, hardware, etc., according to different processing performance, it can be applied in different places to achieve the purpose of automated production and achieve the best results.

Warehouse management

RFID technology has the characteristics of fast identification speed, strong group reading ability, unique serial number, durability, anti-counterfeiting, traceability, etc., and is being used by more and more enterprises to improve their own warehouse management in order to achieve the purpose of reducing costs and increasing efficiency.

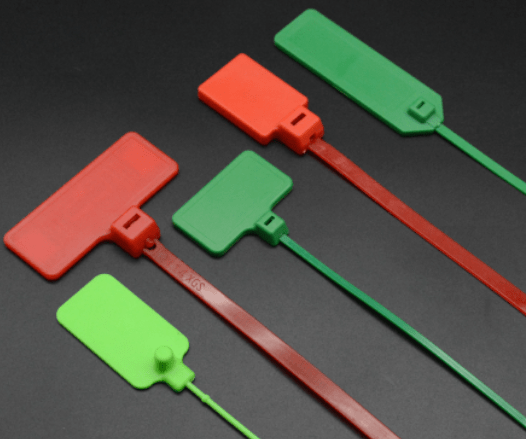

Electronic label plastic seal RFID label ultra-high radio frequency card super induction logistics asset management special

After the goods are processed on the production line, they need to be sent from the production line to the transfer warehouse. RFID reader equipment is installed at the entrance and exit of the transfer warehouse, and combined with the application of RFID handheld devices, it is easy and fast to carry out warehousing, shelving, picking, The collection and verification of on-site business data such as inventory and warehouse delivery realizes the automatic collection of goods information transferred from the production line to the warehouse and real-time background data update. The goods are released from the warehouse, and the automatic and batch release is realized in the same way.

High temperature resistant RFID anti-metal label ABS UHF 18000-6C intelligent management electronic radio frequency label

The RFID warehouse management system is designed and developed based on RFID technology, covering the core storage, inventory, transfer, transfer, etc., as well as a series of basic information, report and other functions, with reliable transmission, intelligent control, data fusion, real-time recording , integrated docking, data analysis and other multi-faceted application value.

Benefits of RFID digital factory

Production data can be updated accurately and in real time

Real-time feedback of production data is the basis for ensuring smooth production and operation. The RFID reading and writing equipment can automatically collect the information in the product label in batches and upload it to the background system in real time. The server can be set to update the data every 5 seconds. Through this mode of operation, the system can provide real-time production data for analysis.

Productivity is improved on the basis of the original

Productivity is the focus of attention of production management and also a difficult point of management. If productivity is improved, it means that the output of the enterprise will increase and the profit will increase. The real-time production data of the production workshop is fed back to the system. Through system monitoring, the reasons that hinder the smooth flow of the production line can be found in real time, and the production bottleneck can be found in time.

RFID Chip - China Electronic Label Manufacturer - RFID Technology Applied to Digital Factory - Wanquan Smart IOT Company

Through real-time data analysis, the system monitors the production status of each workshop, each group, and each station in real time, so that problems in any production link can be found and solved in time, thereby improving the productivity of the factory production line.

Real-time tracking of order progress to ensure delivery time

If the order cannot be delivered in time, it means that the company will not only fail to make a profit but will cause losses, and it will also affect the company's reputation. The future development of the company is greatly affected and hindered. Especially for export enterprises, it is more important for timely delivery of orders. The system starts with customer orders, and treats the real-time progress tracking of the entire production process from the beginning of production to the end of production. Track the progress of orders on the production line in real time, so as to accurately grasp the production progress of each order and achieve the goal of timely delivery.