What is the ABS Sensor on the Car?

ABS sensor, full name Anti-lock Braking System Sensor, is the core component of the anti-lock braking system (ABS) of the car.

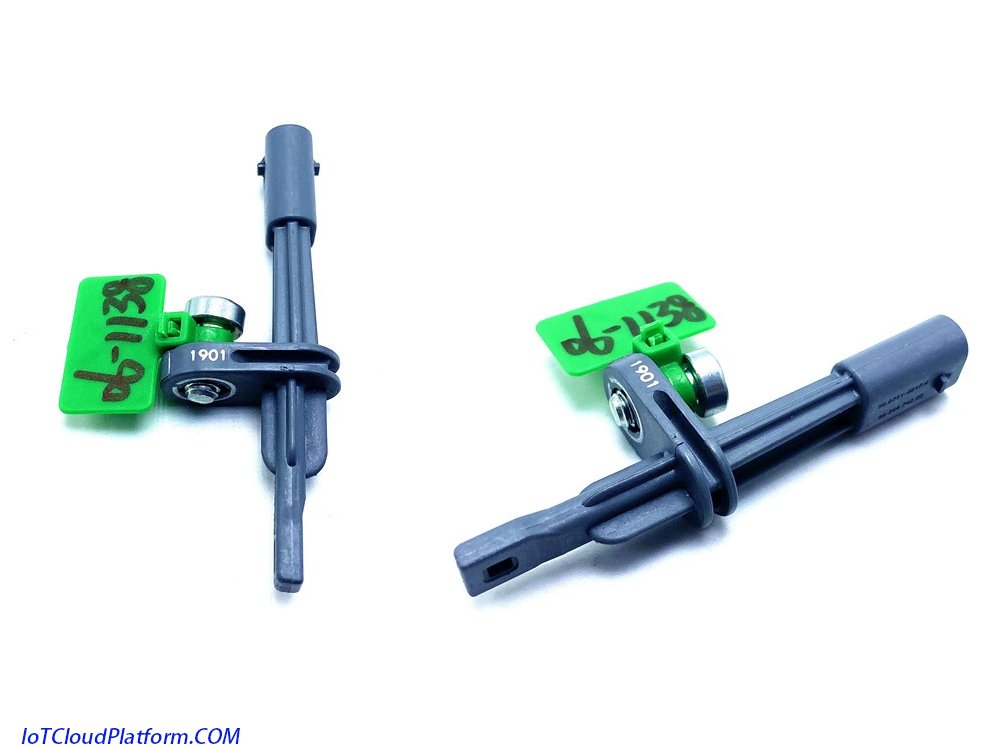

Car ABS Anti-lock Braking Sensor Suitable for ISUZU ABS Speed Sensor

As an important part of the safety performance of modern cars, the ABS system is designed to prevent the wheels from locking during emergency braking, thereby improving the directional stability and steering maneuverability during braking, and shortening the braking distance to ensure driving safety.

Applicable to Toyota ABS sensor anti-lock brake sensor 89542-06110

ABS sensors play a vital role in this system. They are responsible for real-time monitoring of the wheel speed and transmitting the speed information to the ABS control unit (ECU) so that the ECU can quickly adjust the brake pressure according to the change in wheel speed to prevent the wheel from locking.

Working principle of ABS sensor

The working principle of ABS sensor is mainly based on electromagnetic induction or Hall effect. According to different working principles, ABS sensors are mainly divided into two categories: magnetoelectric sensors and Hall sensors.

1. Magnetoelectric sensor

- Composition: Magnetoelectric sensors are usually composed of a magnetic induction head (including permanent magnets, electromagnetic coils and magnetic poles, etc.) and a gear ring. The magnetic induction head is a stationary component installed on the bracket of the wheel; the ring gear is a moving component installed on the wheel hub or axle and rotates with the wheel.

- Working principle: When the ring gear rotates with the wheel, the tooth peaks and tooth valleys of the ring gear will pass through the magnetic induction head in turn. Since there is a certain air gap between the ring gear and the magnetic induction head (generally about 1mm), the rotation of the ring gear will cause the magnetic field strength in the magnetic induction head to change. This change in magnetic field strength will generate an alternating voltage signal in the electromagnetic coil, and the frequency of the signal is proportional to the wheel speed.

- Advantages: The magnetoelectric sensor has a simple structure and low cost.

- Disadvantages: The output voltage signal amplitude changes with the change of wheel speed. When the vehicle speed is very low, the voltage signal output by the sensor may be weak, affecting the accurate judgment of the ECU; the frequency response is low, and when the wheel speed is too high, an erroneous signal may be generated; the ability to resist electromagnetic interference is poor.

2. Hall sensor

- Composition: The Hall sensor consists of a sensor head (including permanent magnets, Hall elements and electronic circuits, etc.) and a gear ring. The sensor head is a stationary component installed on the bracket of the wheel; the gear ring is a moving component installed on the wheel hub or axle and rotates with the wheel.

- Working principle: The Hall sensor uses the Hall effect to work. When the teeth of the gear ring are aligned with the Hall element position, the magnetic lines of force of the permanent magnet pass through the Hall element to the gear, and the magnetic lines of force passing through the Hall element are dispersed between the two teeth. The magnetic field is relatively weak and the Hall element does not generate voltage; when the gear is aligned with the Hall element position, the magnetic lines of force passing through the Hall element are concentrated on one tooth, the magnetic field is relatively strong, and the Hall element generates voltage. As the gear ring rotates, the density of the magnetic lines of force passing through the Hall element changes continuously, causing the Hall voltage to change, thereby outputting a millivolt-level quasi-sine wave voltage. This voltage is converted into a standard pulse voltage signal by a waveform conversion circuit and input into the ECU.

- Advantages: The voltage signal amplitude output by the Hall sensor is not affected by the wheel speed, and the signal is stable and reliable; the frequency response is high, and the wheel speed can be accurately detected even at high speeds; the ability to resist electromagnetic interference is strong.

Role of ABS Sensor

ABS sensors play a vital role in the ABS system. Their main functions include:

1. Real-time monitoring of wheel speed:

ABS sensors can monitor the wheel speed in real time and transmit the speed information to the ECU. This is the basis for the ABS system to achieve anti-lock braking function.

Applicable to Chery A3 sedan ABS wheel sensor front and rear speed sensor

2. Prevent wheel lock:

By monitoring the wheel speed, the ECU can determine whether the wheel is about to lock. Once it is found that the wheel has a tendency to lock, the ECU will immediately adjust the brake pressure to prevent the wheel from locking. This helps to improve directional stability and steering maneuverability during braking.

3. Improve braking efficiency:

The ABS system can prevent the wheel from locking, so that the wheel can maintain maximum adhesion with the ground, thereby giving full play to the braking efficiency of the car and shortening the braking distance.

4. Indirect tire pressure monitoring:

In some vehicles, ABS sensors can also be used to indirectly monitor tire pressure. By comparing the speed differences of different wheels, it is possible to preliminarily determine whether the tire pressure is normal. If the speed of a wheel is significantly lower than that of other wheels, it may be due to the low tire pressure of that wheel.

5. Provide speed signals for other systems:

In addition to the ABS system, some other safety systems (such as the ESP electronic stability program system) also require wheel speed signals to implement their functions. ABS sensors can provide accurate wheel speed signals for these systems.

Installation and location of ABS sensors

ABS sensors are usually installed on the bracket of the wheel, close to the bearing or hub of the wheel. They are fixed to the steering knuckle (shroud shaft) by a screw to ensure that the sensor and the wheel gear ring maintain a certain gap (generally around 0.5±0.15mm). The size of this gap has a great impact on the performance of the sensor. If the gap is too large or too small, the sensor may not be able to accurately detect the wheel speed.

ABS sensor fault and diagnosis

ABS sensor is one of the key components of ABS system, and its performance directly affects the normal operation of the whole system. Therefore, it is very important to find and eliminate the fault of ABS sensor in time.

- Common faults

- Sensor damage: Due to long-term use or external impact, ABS sensor may be damaged, resulting in failure to work properly.

- Signal line fault: The signal line of the sensor may be broken or short-circuited due to wear, aging or extrusion, resulting in failure of signal transmission.

- Gear ring damage or contamination: The gear ring working with the sensor may cause abnormal signal due to wear, deformation or contamination.

- Improper gap adjustment: If the gap between the sensor and the gear ring is not adjusted properly, it will also affect the performance of the sensor.

- Fault diagnosis method

- Use fault diagnosis instrument: Modern cars are usually equipped with fault diagnosis instrument (such as OBD-II diagnostic instrument), which can judge whether the ABS sensor is faulty by reading fault codes and data streams.

- Check the appearance of the sensor: Check whether the appearance of the sensor is damaged, deformed or corroded.

- Measure sensor resistance: Use a multimeter to measure the resistance value of the sensor to determine whether the sensor is normal.

- Check the signal line: Check whether the sensor’s signal line is open, short or in poor contact.

- Adjust the gap: If you suspect that the gap adjustment is improper and causes abnormal sensor performance, you can try to adjust the gap and retest.

Maintenance and care of ABS sensors

In order to ensure the normal operation of the ABS sensor, it is necessary to perform regular maintenance and care on it. The following are some common maintenance and care measures:

- Regularly check the appearance of the sensor: Regularly check whether the appearance of the sensor is damaged, deformed or corroded. If there is any abnormality, it should be replaced in time.

- Clean the sensor surface: Since the sensor is installed close to the wheel and the ground, it is easily eroded by pollutants such as dust, mud and water. Therefore, it is necessary to clean the sensor surface regularly to ensure that it can work properly.

- Check the signal line: Regularly check whether the sensor’s signal line is worn, aged or squeezed. If there is any abnormality, it should be replaced or repaired in time.

- Adjust the gap: Regularly check whether the gap between the sensor and the gear ring meets the requirements. If there is any deviation, it should be adjusted in time.

ABS sensor for Dongfeng Fengshen Yixuan B012583 9824474280

Development trend of ABS sensor

With the continuous development of automobile technology, ABS sensors are also constantly improving and innovating. In the future, the development trend of ABS sensors may include the following aspects:

- Improve accuracy and reliability: By adopting more advanced materials and processes, improve the accuracy and reliability of sensors to ensure that the ABS system can more accurately monitor wheel speed and adjust brake pressure.

- Integration and intelligence: Integrate ABS sensors with other sensors (such as wheel speed sensors, tire pressure sensors, etc.) to achieve information sharing and collaborative work. At the same time, introduce intelligent algorithms and technologies to improve the sensor’s adaptive ability and fault diagnosis ability.

- Reduce cost and energy consumption: Reduce production costs and energy consumption by optimizing sensor structure and production process. At the same time, develop more efficient signal processing algorithms and circuit designs to improve the energy efficiency of sensors.

- Enhance anti-interference capability: Aiming at the impact of external factors such as electromagnetic interference on sensor performance, strengthen the anti-interference capability design of the sensor to ensure that the sensor can work stably in complex environments.

Summary

As one of the key components in the anti-lock braking system of automobiles, ABS sensors play an important role in ensuring driving safety. By real-time monitoring of wheel speed and transmitting speed information to ECU, ABS sensors enable ECU to quickly adjust brake pressure, prevent wheel lock, and improve directional stability and steering maneuverability during braking.

Vehicle instrument ABS wheel speed sensor 89516-0C050 Applicable to Toyota 89516-0C040

At the same time, ABS sensors also have functions such as indirect monitoring of tire pressure and providing speed signals to other systems. In order to ensure the normal operation of ABS sensors, they need to be regularly maintained and repaired, and faults must be discovered and eliminated in a timely manner.

With the continuous development of automobile technology, ABS sensors are also constantly improving and innovating to meet higher requirements for driving safety.

What is the ABS Sensor on the Car pdf

About IoT Cloud Platform

IOT Cloud Platform (blog.iotcloudplatform.com) focuses on IOT solutions, automotive sensors, WiFi modules, sensors, smart home sensors, smart cities, automotive IoT systems, RFID, lora devices, IoT systems, IOT modules, embedded development, photovoltaic solar energy, lithium batteries, chips and other scientific and technological knowledge and products.

FAQs

The following are common questions and answers about ABS sensors on cars:

The ABS sensor is a key component of the anti-lock braking system (ABS). It is used to monitor the speed of the wheel in real time and transmit the speed information to the ABS control unit (ECU) to ensure the stability and safety of the vehicle during braking.

ABS sensor failure will cause the ABS system to fail and the ABS warning light on the dashboard will light up. During emergency braking, the wheels may lock, causing the vehicle to skid and lose control, seriously affecting driving safety.

Common causes of ABS sensor failure include:

The sensor plug is not tightened or the line connection is poor.

The sensor surface is covered with dirt such as dirt and dust.

The internal components of the sensor are damaged, such as short circuit or open circuit of the induction coil.

The gap between the sensor and the gear ring is improper.

The quality problem of the sensor itself.

To determine whether the ABS sensor is faulty, you can use the following methods:

Check whether the ABS warning light on the dashboard is on.

Use a fault diagnosis instrument to read the fault code of the ABS system to check whether there is any sensor-related fault.

Check the appearance and connection of the sensor to confirm whether it is damaged or loose.

Measure the resistance value of the sensor to determine whether it is within the normal range.

To deal with ABS sensor failure, you can take the following measures according to the specific situation:

Clean the dirt on the surface of the sensor to ensure that the sensor can work normally.

Check and tighten the sensor plug and line connection to ensure smooth signal transmission.

If the internal components of the sensor are damaged, you need to replace a new sensor.

Adjust the gap between the sensor and the gear ring to ensure that it meets the specified requirements.

If the sensor itself has quality problems, it is recommended to choose original accessories or reliable replacements.

To prevent ABS sensor failure, the following measures can be taken:

Regularly maintain and service the vehicle and check the working status and connection of the sensor.

Avoid driving for a long time under bad road conditions to reduce the risk of sensor damage.

Pay attention to avoid high-pressure water directly impacting the sensor when washing the vehicle to prevent the sensor from being damaged by water.

When replacing the sensor, choose accessories with reliable quality and install and debug according to the specifications.

ABS sensor failure can seriously affect driving safety. During emergency braking, the wheels may lock due to the failure of the ABS system to work properly, causing the vehicle to skid and lose control. This will not only increase the braking distance, but also endanger the lives of the driver and passengers. Therefore, once an ABS sensor failure is found, it should be repaired or replaced immediately.