Rata uira: anwenqq2690502116@gmail.com

Te ravea o te mau ravea aravihi o te IoT amuihia e te maehaa o te matini roro uira i roto i te tuhaa o te hamaniraa maramarama

E faaô mai teie tumu parau i te Itenati o te mau mea aravihi o teie tau + Te Mau Mana'o no te Haapiiraa, te mau faaohiparaa i te pae no te roro uira e te maramarama.

Against the background of the rapid development of Internet of Things technology + Te Mau Mana'o no te Haapiiraa, the management concept of the manufacturing industry has been continuously upgraded, and the level of digitalization and intelligence has also been rapidly improved.

Te ravea o te mau ravea aravihi o te IoT amuihia e te maehaa o te matini roro uira i roto i te tuhaa o te hamaniraa maramarama

Especially for discrete manufacturing, intelligent means can solve many problems in the traditional management process:

• Data fragmentation: A large amount of enterprise data stays in discrete systems without forming a unified data standard. Some data are still stored in traditional ways such as reports and paper. The source of data is not unique, some data is inaccurate, the underlying collection is incomplete, resulting in the inability to dig deep, manual correction of data is common, some application systems cannot play their due role, and cannot form a data link for big data to support production and operation.

• Incomplete digitalization: ERP is the core of production management in manufacturing enterprises, but many factories have implemented ERP, MES and other systems and found that front-line employees have to manually update business data after completing routine work, which not only increases workload, but also ensures real-time data , Accuracy cannot be guaranteed, and data isolation between systems forms a functional wall.

• Information isolated island: The managers in the production workshop do not know what is happening on the workshop site. Complete information feedback.

It is difficult for managers to make judgments from a global perspective, and the tunnel vision greatly affects the accuracy of business decisions.

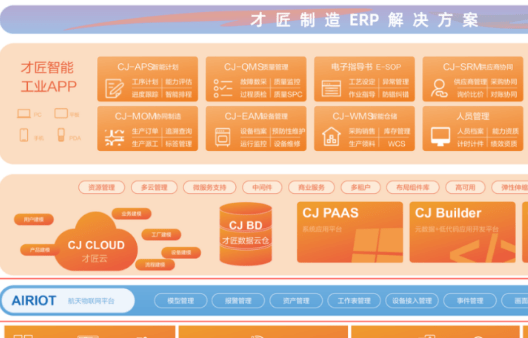

The AIRIOT Internet of Things platform under the military central enterprise Aerospace Science and Technology Holding Group Co., Ltd. integrates the CJ Cloud platform developed by Shanghai Caijiang Intelligent Technology Co., Ltd. to provide discrete manufacturing enterprises with digital and intelligent overall solutions, from raw materials entering the factory to The entire process from the transfer of workers and equipment to the formation of products leaving the factory, records and controls the progress, Te huru â te huru, efficiency, and cost of the production process.

Internet of Things technology realizes data interaction and fusion between different equipment and different scenarios in the manufacturing industry

I mutaa ihora, most factories adopted the "one workshop, one function" model, where each process was separated and there was no connection between different functions. A large workshop after transformation integrates multiple functional departments, and the connection between different functional departments is realized through the Internet of Things technology. When the equipment completes the process, it will send a message, call the AGV system through the application platform, and let the robot send the product to the next process for processing according to the judgment. After the last process is completed, the robot will send the product to the warehouse for shelf.

The digital transformation of discrete manufacturing can be understood as introducing "order" into the loose and disordered discrete manufacturing process, so as to realize the close cooperation between various production factors and production links, and the underlying foundation of this "order" is to realize different equipment, Data interaction fusion between scenes.

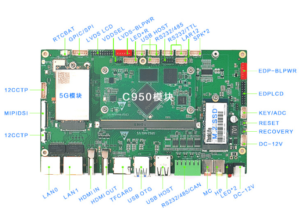

AIRIOT - AIRIOT IoT platform data acquisition and control engine

The data acquisition and control engine of the AIRIOT Internet of Things platform has core capabilities such as massive drive access, distributed clusters, high stability, data interface integration, and linkage alarms. Reliable functions such as device access, application development, configuration services, operation and maintenance management, data statistics and analysis, help solve the problems of on-site device interconnection and data collection in the workshop, and store the cleaned data for development and call. Combined with Caijiang Cloud, a low-code development platform for industrial applications, the collected data is managed in a unified manner through the data cloud warehouse, the real-time performance, accuracy and comprehensiveness of data collection are improved, and the information and data of various departments and factories are shared in a comprehensive manner. Break through the data barriers of various departments and realize the comprehensive integration of production and management data.

Customer IoT case

Caijiang Intelligence and AIRIOT Internet of Things platform built an intelligent manufacturing system for a material factory in Inner Mongolia, breaking the information island under traditional management, realizing centralized data management and sharing, and establishing the CJ-Cloud Caijiang cloud and equipment interconnection platform to reduce manual operations Frequency, to achieve accurate accounting of standard costs, to provide real-time monitoring and abnormal early warning of the operating status of the enterprise. At the data application level, it provides comprehensive cross-business, cross-system, and cross-year drill-through analysis of enterprise data, analyzes the causes of problems layer by layer, and directly hits the root of the problem.

The intelligent manufacturing system covers applications such as digital twins, industrial equipment IoT, production collaboration, intelligent warehousing, and supply chain collaboration. Based on the Caijiang low-code platform, through visualization, drag-and-drop, and modularization, it can realize low-cost, rapid construction of applications and respond to the needs of different businesses, and rapid deployment and delivery according to customers' personalized customization needs.

Through the implementation of the Caijiang Industrial Internet platform, it helps enterprises to open up business management, supply chain and upstream and downstream data, and realize data interconnection in production, Hi'opo'araa maitai, Te mau nota, Te mau mana'o tauturu no te, energy and other links. The production process is transparent, the quality inspection management is standardized, the equipment management is scientific, the warehouse management is digital, the supply chain management is efficient, the energy management is refined, the auxiliary decision-making is intelligent, and the production efficiency and quality are greatly improved.

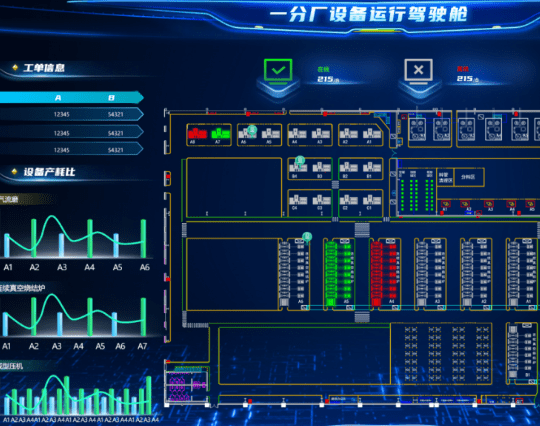

I te hoê â taime, the AIRIOT visual configuration engine is used to present the layout of factory equipment and facilities and industrial processes in the form of visual configuration, and to display the collected key parameter data of equipment operation in real time. Combining the AIRIOT data analysis engine capabilities, the collected data is analyzed in real time, and the insight data is analyzed from different dimensions in the form of data views.

IoT devices run the cockpit - equipment operation cockpit - iot solutions

The AIRIOT Internet of Things platform supports seamless connection with mainstream digital twin platforms to achieve strong interaction, establish real-time mirroring of equipment, taata, materials, and goods in the digital space, and present real-time trajectory of materials, animation of machine tool operators, and real-time production status in a 3D visualization manner Real-time, accurate and comprehensive business data and situation, such as changes, real-time working status of machine tools, e te vai atu ra., what you see is what you get.

TE MAU NOTA - iot solutions

The data acquisition and control engine of the AIRIOT Internet of Things platform connects the Internet of Things gateway with field devices, collects field device data in real time, uses the communication function of the gateway in a timely manner when problems are found, and establishes a data channel with field devices through the AIRIOT Internet of Things platform, oia ho'i, realizes device monitoring. Diversified remote control functions such as remote maintenance, remote debugging and program download.

Internet of things remote control

With the demand for high-quality development, more and more leading manufacturing industries have stricter requirements for quality traceability. Quality management requirements can be traced back to what the equipment is doing, whether it is powered on, how the equipment is operating, and even requires quality management to be traced back to Operating parameters during processing.

Based on the AIRIOT Internet of Things platform, Caijiang Industrial Internet Solution provides a quality management system that can collect and record data in the production process in real time, solve quality control problems in the production process, and help companies achieve standardized quality that can be traced throughout the product life cycle Control.

The system integrates a variety of quality inspection schemes from research and development, procurement, faahoturaa, sales and other multi-business processes in the manufacturing process. The quality information flow can cover all elements of human, Te mau mana'o tauturu no te, method, material, environment, and testing to build a complete product quality traceability system.

I te hoê â taime, combined with the visual configuration engine of the AIRIOT Internet of Things platform, which has the ability to look back on the screen, enterprises can replay the data in the production process in real time and restore the production scene. These data can be combined with the AI algorithm model to realize data analysis and processing, optimize the processing process, and form a complete product tracking and quality tracking system.

Through strict control and supervision of each link, the reliability of product quality is ensured, thereby improving production efficiency and making production more transparent, efficient and reliable.

The AIRIOT IoT platform provides a digital base for the digital transformation of the discrete manufacturing industry, realizes collaborative manufacturing, process traceability and information sharing of the discrete manufacturing production management, further promotes the digital and intelligent development of the manufacturing industry, and enhances the competitiveness and competitiveness of enterprises. Production efficiency brings a broader development space for the manufacturing industry in the new era.