Email: anwenqq2690502116@gmail.com

5 Common IoT Solutions for 2023. The IoT solution is analyzed and customized according to the actual situation of the IoT project, so the IoT solution in this article is only used as a learning reference.

How to realize network segment isolation and cross-network segment access of multiple sewage treatment PLCs, online monitoring system solution for water, rain and water level in flood storage and detention areas, how to realize cross-network segment access and network segment isolation for smart water multi-equipment, SL651 data collection to achieve real-time hydrological monitoring, help flood prevention and disaster reduction work to be carried out in an orderly manner, industrial intelligent gateway to realize PLC data acquisition and remote monitoring.

5 Common IoT Solutions for 2023

-

How to realize network segment isolation and cross-network segment access of multiple sewage treatment PLCs

As wastewater treatment plants become larger, more and more devices may be connected to the site. These equipment need to be connected to the automatic control system one by one to achieve digital management, which can effectively improve the efficiency of sewage treatment and reduce operating costs. However, the following problems are often encountered: the IP of the new device cannot be modified and cannot be connected to the network; Devices in different network segments cannot communicate with each other, and device management is difficult. IP conflicts make network planning and management difficult; Cyberattacks can lead to data breaches.

Online Water Level Detection System for Bridge Tunnels - Internet of Things Remote Warning System - 5 common IoT solutions in 2023

In response to the above problems, IoT has launched a network segment isolator (NAT translation gateway) to realize network communication and data collection in production networks such as PLC, HMI, CNC, DCS, MES, etc., and has cross-network segment isolation and IP translation functions. It can unify multiple devices on the site of the sewage treatment plant into the IP address of the same network segment, and can carry out various cross-network segment access such as online programming, data collection, and remote management of equipment (PLC, CNC), which can effectively solve the problem of the internal network of the enterprise. Communication problems and security issues to ensure the security and reliability of enterprise data.

PLC network segment isolation and cross-network segment access application scenarios

(1) Solve the problem that the IP address of the newly purchased device cannot be modified and cannot be connected to the network

(2) Through NAT translation, solve the problem that devices in different network segments cannot communicate

(3) Through IP renaming, realize unified IP planning and management of production networks

(4) Through IP renaming, solve the problem of hiding the real IP of the device and preventing network attacks

(5) Through firewall network segment isolation and port restrictions, effectively improve network interference and attack capabilities

-

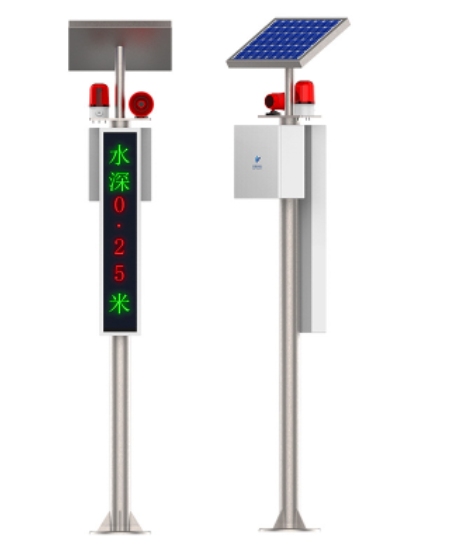

Online monitoring system solution for water, rain and water level in flood storage and detention areas

Flood storage and detention areas are an important part of China's flood defense system. They are low-lying areas and lakes outside river embankments that temporarily store floodwater. It plays an important role in ensuring the safety of production and life in the areas along the river.

In meteorological disasters such as heavy rain and floods, dikes and pumping stations can effectively reduce the pressure of flood storage and ensure timely water storage and timely discharge. The facility is operating normally. In this regard, Wutong Bolian provides an efficient and stable data collection gateway to help monitor water, rain and water level data in real time, enhance the management and early warning capabilities of flood storage and detention areas, and protect the surrounding areas from disasters.

Water level online monitoring system function

1. Data collection: connect the gateway with the rain gauge, flow meter, water level meter and other equipment of each weather station, collect real-time rainfall, runoff, real-time water level and other data, and transmit it to the cloud platform monitoring through the wireless network.

2. Over-limit alarm: When the data such as rainfall, flow, water level, and flow rate exceed the threshold, the system will automatically notify the management personnel through WeChat, SMS, email, etc., and inform the alarm point and alarm point information.

3. Remote monitoring: on-site information and data changes can also be viewed through mobile phones or computers, and multi-terminal data sharing is convenient for managers at all levels to understand the information.

4. Data analysis: Through hydrological data, pumping station operation efficiency and other data, rainwater disasters can be quickly judged, and the carrying capacity of flood storage and detention areas can be understood and scientific decisions can be made in time.

-

How to implement cross-network segment access and network segment isolation of multiple smart water devices

In the water system, a variety of industrial equipment is usually deployed on site, such as PLC, water pump, sewage treatment equipment, etc., which may be in different network segments, unable to communicate and interact with each other, affecting data integration and network management. This is one of the issues that plagues the digital transformation of enterprises.

How do I achieve cross-segment access and network segment isolation?

It can be implemented through IoT-Bolian NAT translation gateway (network segment isolator). The network segment isolator is suitable for network communication and data acquisition in production networks such as PLC, HMI, CNC, DCS, MES, etc., with cross-network segment isolation and IP conversion functions.

Support network segment isolation and NAT translation of more than 4 devices (such as PLC, CNC, etc.) at the same time; If there are multiple devices in the workshop, if they have IP addresses of different network segments, they can be unified into the IP addresses of the same network segment, and cross-network segment access such as online programming, data transmission collection, and remote management of equipment (PLC, CNC and other CNC) can be carried out.

Through network segment isolation, you can improve the access and communication capabilities between different network segments while maintaining the original network foundation, so as to avoid potential network attacks and data leaks. In addition, network segment isolation can also divide network IP into simpler management units, making network management more concise and efficient. Administrators can more easily configure, monitor, and maintain devices under different network segments, reducing the complexity of troubleshooting and management.

(1) Solve the problem that the IP address of the newly purchased device cannot be modified and cannot be connected to the network

(2) Through NAT translation, solve the problem that devices in different network segments cannot communicate

(3) Through IP renaming, realize unified IP planning and management of production networks

(4) Through IP renaming, solve the problem of hiding the real IP of the device and preventing network attacks

(5) Through firewall network segment isolation and port restrictions, effectively improve network interference and attack capabilities

-

SL651 data collection realizes real-time hydrological monitoring, helping flood prevention and disaster reduction work to be carried out in an orderly manner

The SL 651 protocol is a communication protocol for hydrological monitoring data, which is used in reservoir monitoring stations, data acquisition and transmission systems, and IoT platforms that provide data monitoring and analysis services.

The industrial intelligent gateway with SL651 data collection capability provided by Wutong Bolian is connected with supervision platforms at all levels to realize real-time collection, reporting, processing and analysis of water level, rainfall, flow, water quality and other data. River and reservoir data, providing a platform for information sharing. Transparent and timely, it provides a scientific basis for the prevention and control of hydrometeorological disasters and guarantees the safety of people's lives and property.

SL651 data acquisition IoT system functions

Real-time data collection: The real-time hydrological monitoring system can collect equipment data such as sensors and hydrological data through the gateway, including parameters such as water level, flow rate, and water quality.

Data transmission and storage: The gateway transmits the collected data to the cloud platform through wired or wireless networks to facilitate subsequent data analysis and processing.

Data analysis and processing: The monitoring system can perform real-time statistical analysis and processing on the collected data, including data plotting, calculation, trend prediction, etc.

Fault alarm: The monitoring system can monitor the abnormal situation of hydrological data in real time according to the set threshold, and issue an alarm when a fault is found or the threshold is exceeded, so that timely measures can be taken.

Remote monitoring: Through mobile phones and computers, users can remotely access the monitoring system, view hydrological data in real time and monitor and manage them, without the need to go to the site for manual operation.

Data display and report generation: It can provide an intuitive data display interface, including charts, curves, etc., and can also help generate reports reflecting hydrological conditions and trend changes.

Data sharing and application: Monitoring systems can provide data interfaces to facilitate data sharing and integration applications, such as data interaction with hydrological models and water resource management systems.

-

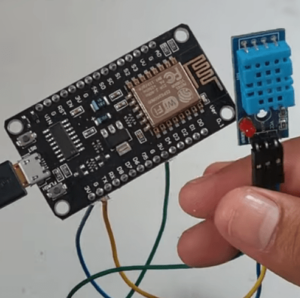

The industrial intelligent gateway realizes PLC data acquisition and remote monitoring

With the continuous development of the industrial Internet, the application scenarios of industrial intelligent gateways (IoT gateways) are becoming more and more extensive.

For example, in the field of intelligent manufacturing, gateways can be used to realize remote monitoring and fault warning of equipment, improve production efficiency and reduce maintenance costs; In the field of energy management, gateways can be used to realize remote energy monitoring and energy-saving optimization, and improve energy efficiency.

The industrial intelligent gateway launched by Wutong Bolian has good adaptability, and can connect Siemens, Mitsubishi, Omron, Schneider, Delta, Huichuan and other PLCs for protocol analysis and data collection, so as to realize remote monitoring and fault alarm, remote control, remote maintenance, etc., to help enterprises manage production equipment more accurately and intelligently.

1. Read the working status of PLC and the status of I/O points controlled by PLC, and display them on the touch screen in real time through configuration, so that managers can understand the working status of PLC and its control equipment in time.

2. The control command issued by the touch screen is sent to the PLC through the gateway, which realizes the two-way communication between the touch screen and the PLC, which can quickly change the status or output of the PLC and realize the rapid control of the equipment PLC.

3. The data collected by PLC can be calculated, processed, stored and displayed at the edge, and data reports can be generated in real time, providing reliable data support for optimizing the production process and improving the process.

4. When there is an abnormal situation such as pressure, temperature or power failure, the abnormal signal output by the PLC can realize rapid alarm through the gateway, and support WeChat, SMS, email and other notification methods.

5. Engineers can remotely program and debug the PLC, upload and download programs remotely through the equipment maintenance express line, improve the maintenance work efficiency, and reduce the frequency and cost of business trips.