ZWIN-AC1008-DPT Digital Dissolved Oxygen PH Temperature Sensors

ZWIN-AC1008-DPT Digital Dissolved Oxygen PH Temperature Sensor is an advanced sensor device that integrates dissolved oxygen, pH and temperature monitoring functions.

It is designed for water quality monitoring and is widely used in aquaculture, environmental monitoring, food production, pharmaceutical industry and other scenarios.

Dissolved oxygen pH temperature sensor for aquaculture

The following is a detailed introduction to the product:

Product Overview

The ZWIN-AC1008-DPT sensor uses advanced measurement technology and precise manufacturing processes to simultaneously and accurately monitor the dissolved oxygen content, pH and temperature in water. Through the integrated design, the installation space and wiring costs are greatly reduced, and the reliability and ease of use of the system are improved. The product has the characteristics of high precision, long life, intelligent control, etc., providing users with a comprehensive, accurate and intelligent water quality management solution.

ZWIN-AC1008-DPT sensor

Product Features

1. High-precision measurement

- Dissolved oxygen monitoring: Using advanced optical measurement technology, the measurement range covers 0-20mg/L, and the accuracy is as high as ±0.3mg/L. Whether in low-oxygen or high-oxygen environments, it can provide stable and reliable dissolved oxygen data, providing strong support for the precise control of oxygenation equipment.

- pH measurement: Using the glass electrode method, the measurement range is 0-14pH, and the accuracy is ±0.1pH. By real-time monitoring of water pH, it helps users to adjust the breeding environment or production process in time to ensure the stability of water quality or products.

- Temperature monitoring: Built-in high-precision PT1000 temperature sensor, the measurement range is 0-50℃, and the accuracy is ±0.1℃. Temperature is one of the important factors affecting water quality and biological growth. By real-time monitoring of water temperature, it provides a scientific basis for optimizing the breeding environment or adjusting the production process.

2. Long-life electrode design

- PH electrode: Industrial-grade composite electrode is selected, and the reference electrode adopts a double salt bridge design, which greatly extends the service life of the electrode and reduces the frequency and cost of replacing the electrode.

- Dissolved oxygen measurement: The electrolyte-free design is adopted, and the dissolved oxygen membrane does not need to be replaced regularly, which reduces maintenance costs and improves the overall durability of the equipment.

3. Intelligent control function

- The device supports setting thresholds for dissolved oxygen, pH and temperature. When the monitoring data exceeds the set range, it can automatically trigger an alarm or control the oxygenation equipment, adjust the pH value, etc., to achieve intelligent management of the breeding environment or production process.

- Users can view water quality data in real time through mobile phone apps and computer web pages, breaking geographical restrictions, grasping water quality anytime and anywhere, and adjusting breeding strategies or production processes in time.

4. Easy to install and maintain

- The sensor adopts an integrated design, compact structure and easy installation. Users only need to follow the instructions for simple operations to complete the installation.

- The sensor supports RS485 wired transmission and wireless access to the network platform, and is flexibly adapted to local or cloud monitoring systems. During maintenance, users can easily access sensor data for troubleshooting and calibration operations.

5. High protection level

- The sensor adopts IP68 protection level design, which can effectively resist corrosion, dirt and mechanical impact in water quality, ensuring stable operation of the equipment in harsh environments.

ZWIN-AC1008-DPT Digital Dissolved Oxygen PH Temperature Sensor Specifications

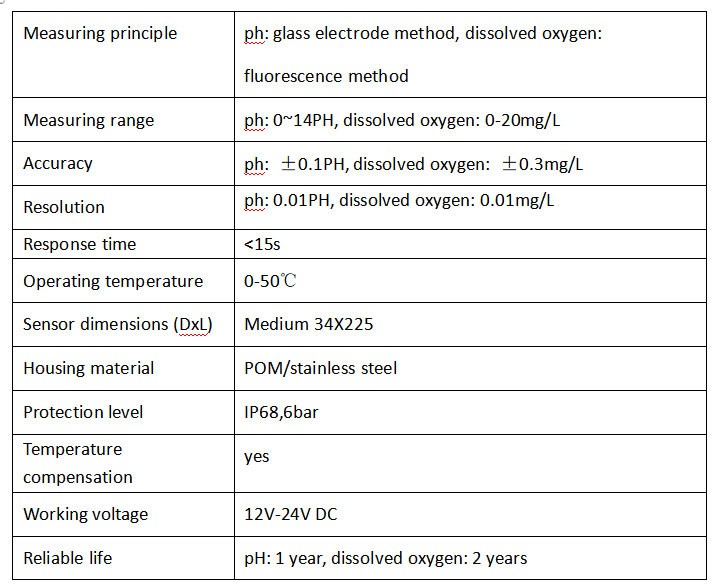

Technical parameters

| Measuring principle | ph: glass electrode method, dissolved oxygen: fluorescence method |

| Measuring range | ph: 0~14PH, dissolved oxygen: 0-20mg/L |

| Accuracy | ph: ±0.1PH, dissolved oxygen: ±0.3mg/L |

| Resolution | ph: 0.01PH, dissolved oxygen: 0.01mg/L |

| Response time | <15s |

| Operating temperature | 0-50℃ |

| Sensor dimensions (DxL) | Medium 34X225 |

| Housing material | POM/stainless steel |

| Protection level | IP68,6bar |

| Temperature compensation | yes |

| Working voltage | 12V-24V DC |

| Reliable life | pH: 1 year, dissolved oxygen: 2 years |

Application scenarios

- Aquaculture:

- Real-time monitoring of dissolved oxygen, pH and temperature in aquaculture water to provide a suitable growth environment for aquatic organisms such as fish.

- Improve aquaculture efficiency and product quality through intelligent control of oxygenation equipment, adjustment of pH value, etc.

- Environmental monitoring:

- Monitor dissolved oxygen, pH and temperature in water bodies such as rivers, lakes and reservoirs to evaluate water quality.

- Provide accurate water quality data to environmental protection departments to support environmental management and decision-making.

- Food production:

- Monitor water quality during food processing to ensure that products meet hygiene standards and safety requirements.

- Improve production efficiency and product quality by real-time monitoring and adjustment of water quality.

- Pharmaceutical industry:

- Monitor dissolved oxygen, pH and temperature in pharmaceutical water to ensure that water quality meets production requirements.

- Ensure the quality and safety of medicines through high-precision measurement and intelligent control.

Installation and maintenance

Installation:

- Select a suitable installation location according to the usage scenario and monitoring requirements.

- Install according to the instructions to ensure that the sensor is in full contact with the water body and the connection is stable and reliable.

- Configure communication parameters and calibrate sensors to ensure measurement accuracy.

Maintenance:

- Regularly check the working status and measurement data of the sensor, and handle any abnormalities in a timely manner.

- Clean the sensor and replace wearing parts such as electrodes regularly according to the usage and instructions.

- Calibrate the sensor regularly to ensure measurement accuracy.

Summary

ZWIN-AC1008-DPT digital dissolved oxygen PH temperature sensor is an advanced water quality monitoring device that integrates high precision, long life and intelligent control. It is widely used in aquaculture, environmental monitoring, food production, pharmaceutical industry and other scenarios, providing users with comprehensive, accurate and intelligent water quality management solutions.

By real-time monitoring of water quality parameters and intelligent control of oxygenation equipment, pH adjustment, etc., the sensor helps to improve breeding efficiency, product quality and environmental management level. At the same time, its easy installation and maintenance characteristics also reduce the user’s use cost and maintenance difficulty.

ZWIN-AC1008-DPT Sensor Specifications

About IoT Cloud Platform

IOT Cloud Platform (blog.iotcloudplatform.com) focuses on IOT solutions, low-altitude economic IoT, WiFi modules, sensors, smart home sensors, smart cities, RFID, lora devices, IoT systems, IOT modules, embedded development, photovoltaic solar energy, lithium batteries, chips, IOT circuit boards, Raspberry Pi development and design, Arduino programming, new energy, semiconductors and other scientific and technological knowledge and technology products.

FAQs

Here are some frequently asked questions and answers about the ZWIN-AC1008-DPT digital dissolved oxygen pH temperature sensor:

Check if the sensor is covered with dirt and wipe it clean with a clean soft cloth or soft brush.

Check if the sensor is aged. If it is severely aged, it is recommended to replace it with a new sensor.

Recalibrate the sensor to ensure that the calibration process is accurate.

The measuring cable may be subject to electromagnetic interference. Please check and correctly connect the cable shielding wire and try to wire it independently.

Check the sensor installation position to avoid the influence of turbulent liquid flow rate or large bubbles.

Confirm that the sensor membrane sleeve is not damaged. If necessary, replace the membrane sleeve and recalibrate.

Check if the data cable is plugged in and the connection is firm.

Confirm that the communication protocol of the sensor and the data recording device is consistent.

Check if the data recording device is working properly. If there is a problem, please contact the equipment supplier.

Clean the sensor to remove dirt that may affect the measurement.

Check whether the sensor is used within the specified operating range and avoid overloading or improper use.

Recalibrate the sensor to ensure that the calibration fluid matches the measuring fluid and the calibration process is accurate.

Clean and maintain the sensor regularly to avoid dirt accumulation.

Choose a suitable installation location to avoid frequent thermal cycles, chemical corrosion or mechanical wear.

Replace the electrode or sensor component regularly according to the manufacturer’s recommendations.

The sensor has an IP68 protection rating and can effectively resist corrosion, dirt and mechanical impact in the water.

For particularly harsh environments, you can consider additional protection measures, such as using a protective cover or regularly replacing the protective film.

Avoid exposing the sensor to extreme temperature or humidity conditions for a long time.

Calibrate the sensor with a standard calibration fluid to ensure that the calibration fluid is within the validity period and is not contaminated.

Follow the calibration steps in the sensor’s operating manual and record the data before and after calibration for comparison.

Calibrate the sensor regularly to ensure the accuracy of the measurement data.

Check whether the connection between the sensor and the power supply is normal and whether the power supply is stable.

Check whether there are damaged or loose parts inside the sensor.

If you cannot solve the problem yourself, please contact the sensor supplier or professional technicians for repair.

Make sure the sensor is installed correctly according to the manufacturer’s instruction manual to avoid measurement errors caused by improper installation.

During the installation process, be careful to avoid mechanical damage or chemical corrosion to the sensor.

Choose a suitable installation location to ensure that the sensor can accurately measure the parameters of the measured liquid.

Yes, the sensor requires regular maintenance to maintain its accuracy and stability.

Clean the sensor surface and internal components regularly, and check the status of the cable and connectors.

Depending on the use of the sensor, replace the wearing parts regularly or replace them as a whole.