Will biofilms on sensor probe surfaces interfere with readings?

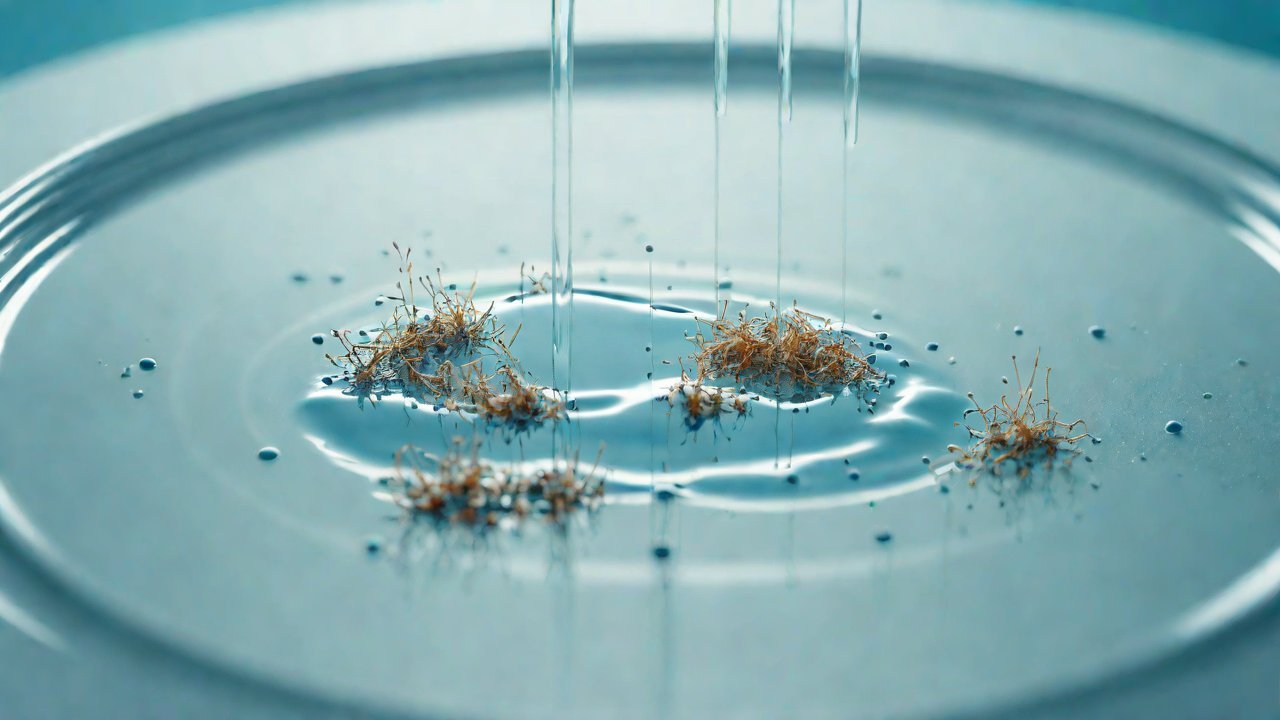

Biofilms, complex communities of microorganisms that adhere to a surface, have been found in almost every environment imaginable, from pristine mountain lakes to industrial processing equipment. These microbial aggregates can have significant effects on their surroundings, influencing everything from water quality to food safety and even the performance of electronic devices.

In the realm of sensor technology, biofilms pose a particular challenge due to their potential to interfere with readings. Sensor probes are ubiquitous in various industries, including healthcare, environmental monitoring, and industrial process control. These sensors rely on accurate data collection to provide critical insights into complex systems.

However, when sensor probe surfaces become encrusted with biofilm, the reliability of these devices can be compromised. Biofilms can alter the physical properties of the surface, such as roughness and hydrophobicity, which may affect the accuracy of sensor readings. Moreover, microorganisms within the biofilm can also produce extracellular polymeric substances (EPS) that can coat the sensor probe, further impacting data quality.

1. Biofilm Formation on Sensor Probe Surfaces

Biofilms form through a complex process involving multiple steps:

- Initial Adhesion: Microorganisms adhere to the surface of the sensor probe, often facilitated by electrostatic forces or specific adhesins.

- Reorganization and Maturation: Once adhered, microorganisms begin to reorganize themselves into a more structured community, producing EPS and other extracellular compounds.

- Growth and Metabolism: As biofilm matures, microorganisms continue to grow and metabolize their surroundings, further altering the surface properties.

Factors Influencing Biofilm Formation

Several factors can influence the likelihood of biofilm formation on sensor probe surfaces:

| Factor | Description |

|---|---|

| Surface Topology | Smooth or rough surfaces may affect microbial adhesion. |

| Material Composition | Certain materials, such as stainless steel or glass, are more prone to biofilm formation than others. |

| Environmental Conditions | Temperature, pH, and nutrient availability can impact biofilm growth. |

2. Impact of Biofilms on Sensor Readings

The presence of biofilms on sensor probe surfaces can have significant effects on data quality:

- Sensor Calibration: Biofilm-coated sensors may require recalibration to maintain accuracy.

- Data Drift: Changes in surface properties due to biofilm growth can lead to gradual changes in sensor readings over time.

- Interference with Signal Processing: In some cases, biofilms can directly interfere with signal processing algorithms or even damage the sensor itself.

Case Study: Industrial Process Control

A study conducted at a large-scale manufacturing facility found that biofilm formation on temperature sensors led to significant errors in process control. The resulting data inaccuracies caused by biofilms resulted in:

| Error Type | Impact |

|---|---|

| Temperature Inaccuracy | 5-10% error margin |

| Process Yield Reduction | 3-5% decrease |

3. Mitigation Strategies for Biofilm Interference

Several strategies can help mitigate the effects of biofilm interference on sensor readings:

- Regular Cleaning and Maintenance: Regular cleaning with appropriate chemicals or water jets can prevent biofilm accumulation.

- Surface Modification: Applying coatings or modifying surface topologies can reduce microbial adhesion.

- Sensor Design Improvements: Redesigning sensors to be more resistant to biofilm formation, such as using hydrophobic materials or incorporating antimicrobial agents.

Emerging Technologies for Biofilm Management

Researchers are exploring innovative approaches to manage biofilms on sensor probe surfaces:

| Technology | Description |

|---|---|

| Nanomaterial Coatings | Applying nanomaterial coatings that inhibit microbial adhesion. |

| Antimicrobial Peptides | Incorporating antimicrobial peptides into sensor design to prevent biofilm growth. |

4. Conclusion

Biofilm formation on sensor probe surfaces can have significant effects on data quality, impacting the accuracy and reliability of readings in various industries. Understanding the factors influencing biofilm formation and exploring mitigation strategies are crucial for maintaining accurate sensor performance.

By recognizing the risks associated with biofilms and implementing effective management strategies, industries can ensure the continued operation and maintenance of critical systems. Further research into emerging technologies for biofilm management may provide new avenues for addressing these challenges.

IOT Cloud Platform

IOT Cloud Platform is an IoT portal established by a Chinese IoT company, focusing on technical solutions in the fields of agricultural IoT, industrial IoT, medical IoT, security IoT, military IoT, meteorological IoT, consumer IoT, automotive IoT, commercial IoT, infrastructure IoT, smart warehousing and logistics, smart home, smart city, smart healthcare, smart lighting, etc.

The IoT Cloud Platform blog is a top IoT technology stack, providing technical knowledge on IoT, robotics, artificial intelligence (generative artificial intelligence AIGC), edge computing, AR/VR, cloud computing, quantum computing, blockchain, smart surveillance cameras, drones, RFID tags, gateways, GPS, 3D printing, 4D printing, autonomous driving, etc.