What is RF Power Sensor?

RF power sensor is an instrument used to measure the power of RF signals. It has a wide range of applications in wireless communications, RF testing, electronic measurement and other fields.

rf power sensor design – blog.iotcloudplatform.com

The following is a detailed introduction to RF power sensors:

Basic concepts of RF power sensors

RF power sensor is a device that can convert RF signal power into a measurable signal. It is usually used to measure the output power, input power or reflected power of RF devices such as radio transmitters, receivers, antennas, etc. The working principle of RF power sensor is based on the transmission and reception of electromagnetic waves. The power of RF signal is converted into electrical signal through specific sensor elements (such as thermistors, thermocouples, diodes, etc.), and then the power value is obtained after processing.

Classification of RF power sensors

RF power sensors can be divided according to different classification methods:

1. Classification by measurement type:

- Peak power sensor: used to measure the peak power of RF signal. In wireless communications, peak power is one of the important indicators for evaluating signal strength and quality.

- Average power sensor: used to measure the average power of RF signal. Average power sensors can provide more stable measurement results and are suitable for situations where the power of RF signals needs to be monitored for a long time.

2. Classification by measurement range:

- Low power sensor: used to measure RF signals with lower power, such as microwave communication, satellite communication, etc.

- High power sensor: used to measure RF signals with higher power, such as radar, radio and television transmitters, etc.

3. Classification by measurement method:

- Absorption power sensor: measures power by absorbing RF signals and converting them into heat energy. This sensor is usually used in high-power measurement situations.

- Coupled power sensor: measures by coupling part of the RF signal. This sensor is usually used in low-power or medium-power measurement situations.

Working principle of RF power sensor

The working principle of RF power sensor is based on the transmission and reception of electromagnetic waves. When the RF signal passes through the sensor, the components inside the sensor (such as thermistors, thermocouples, diodes, etc.) absorb or couple part of the RF signal and convert it into an electrical signal. Then, this electrical signal is processed by the processing circuit (such as amplification, filtering, demodulation, etc.) to obtain the power value.

Take the diode power sensor as an example, its working principle is as follows:

- When the RF signal passes through the sensor, the diode will rectify the RF signal and convert it into a DC signal.

- This DC signal is proportional to the power of the RF signal.

- By measuring the size of the DC signal, the power value of the RF signal can be obtained.

Key parameters of RF power sensor

The performance of the RF power sensor depends on several key parameters, which determine the measurement accuracy, range and stability of the sensor:

1. Frequency range:

Refers to the frequency range of the RF signal that the sensor can measure. Different RF power sensors have different frequency ranges, and users should choose according to actual needs when selecting.

2. Power range:

Refers to the power range of the RF signal that the sensor can measure. This range determines the maximum and minimum power values that the sensor can handle.

3. Power linearity:

Refers to the linear relationship between the sensor output signal and the RF signal power. The better the linearity, the higher the accuracy of the measurement result.

4. Dynamic range:

Refers to the range between the maximum and minimum values of the RF signal power that the sensor can measure. The larger the dynamic range, the wider the signal range that the sensor can handle.

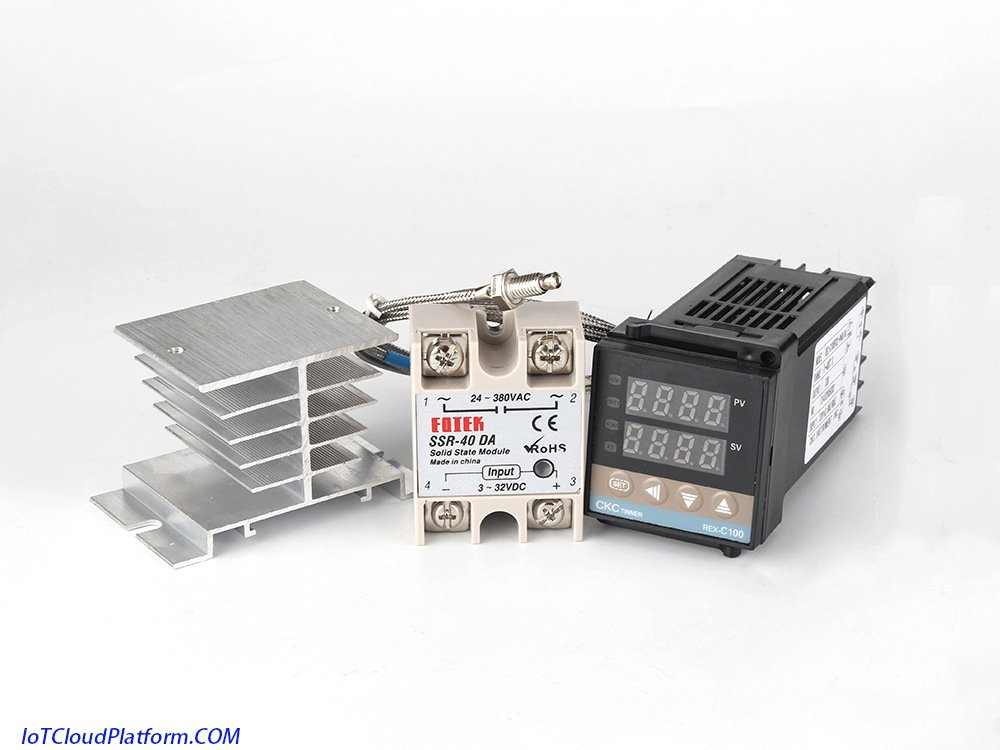

REX-C100 Thermostat 40DA solid state / temperature sensing line temperature control high power intelligent temperature control

5. Standing wave ratio (VSWR):

Refers to the reflection coefficient of the sensor input port. The smaller the VSWR, the better the match between the sensor and the RF signal source, and the higher the accuracy of the measurement results.

6. Response time:

Refers to the time required for the sensor to output a stable power value from receiving the RF signal. The shorter the response time, the faster the sensor responds to changes in the RF signal.

Application of RF power sensors

RF power sensors have a wide range of applications in wireless communications, RF testing, electronic measurement and other fields:

1. Wireless communication:

- Transmitter power monitoring: Used to monitor the output power of the wireless transmitter to ensure that it works within the specified range.

- Receiver sensitivity test: By measuring the input power of the receiver, its ability to receive weak signals is evaluated.

2. RF test:

- Antenna test: used to measure the gain, directivity and other parameters of the antenna to evaluate its performance.

- Filter test: By measuring the power values before and after the filter, evaluate its insertion loss and out-of-band suppression performance.

3. Electronic measurement:

- Power meter calibration: RF power sensors are often used to calibrate power meters to ensure the accuracy of their measurement results.

- Signal source calibration: used to calibrate the output power of the signal source to ensure that it works within the specified range.

Development trend of RF power sensors

With the continuous development of wireless communication technology and the continuous expansion of application fields, RF power sensors are also constantly innovating and developing.

RF Power Sensor Appearance Design

The following are some development trends of RF power sensors:

1. High frequency:

With the development of wireless communication technology towards high frequency bands, RF power sensors also need to have a wider frequency range and higher measurement accuracy.

2. Miniaturization:

In order to meet the needs of portable devices and embedded systems, RF power sensors are developing towards miniaturization and microminiaturization.

3. Intelligent:

With the popularization of IoT and AI technologies, RF power sensors are also beginning to have intelligent functions, such as automatic calibration and remote monitoring.

4. Multifunctional:

In order to meet the needs of complex application scenarios, RF power sensors are developing in the direction of multifunctionality, such as having power measurement, frequency measurement, phase measurement and other functions at the same time.

Selection and use precautions of RF power sensors

When selecting and using RF power sensors, users need to pay attention to the following points:

- Selection:

- Frequency range: Select the appropriate frequency range according to actual needs.

- Power range: Ensure that the sensor can handle the power range of the measured RF signal.

- Accuracy and stability: Select the appropriate accuracy and stability level according to application requirements.

- Interface and size: Ensure that the sensor matches the interface and size of the test system.

- Precautions for use:

- Calibration: Calibrate the RF power sensor before use to ensure the accuracy of its measurement results.

- Matching: Ensure good matching between the sensor and the RF signal source to be measured to reduce reflection and standing wave ratio.

- Protection: Avoid the sensor from adverse effects such as overpower shock and high temperature to extend its service life.

- Storage: When not in use, store the RF power sensor in a dry, ventilated, non-corrosive gas environment.

Specific products and application cases of RF power sensors

(I) Specific products

Take the US BIRD 7020-1-030301 RF power sensor as an example. The product has the following features:

- Wide frequency range: Supports a wide frequency range of 25 MHz to 1.0 GHz.

- High accuracy: Adopts a dedicated power conversion circuit with high accuracy and stability.

- Plug and play: No field calibration is required, only factory calibration is required once a year, and it can be traced back to the National Institute of Standards and Technology (NIST).

- Multi-function: Able to measure forward and reflected true average power and VSWR.

This product is widely used in analog cellular, digital cellular, 3G, 4G, Tetra, APCO/P25, cluster, CDMA, TDMA, WCDMA, GSM, transportation, tactical military, radar, avionics, ships, LMR, analog broadcast, digital broadcast, GSM, GPRS, EDGE, UMTS, HSDPA, Bluetooth, fire, GPS, NPSPAC, paging, Project 25, public safety, telematics, utilities, WIMAX and WLAN.

NTC Temperature Sensor – Home Appliances Electronics New Energy Sensor

(II) Application Cases

Wireless Communication Transmitter Power Monitoring:

- Scenario Description: In a wireless communication base station, the output power of the transmitter needs to be monitored in real time to ensure that it complies with relevant standards and specifications.

- Solution: Use an RF power sensor connected to the transmitter output port to monitor its output power in real time. Through the data acquisition and analysis system, the power value is displayed on the monitoring screen, and the threshold alarm function is set to alarm in time when the output power exceeds the range.

Antenna gain test:

- Scenario description: In a certain antenna R&D laboratory, it is necessary to perform a gain test on the newly developed antenna.

- Solution: Use an RF power sensor connected between the signal source and the antenna to measure the signal source output power and the antenna receiving power. By calculating the power ratio, the gain value of the antenna is obtained. At the same time, it can also be combined with the darkroom test system to comprehensively test the directivity and polarization characteristics of the antenna.

RF Power Sensor Application Cases

Technical challenges and future prospects of RF power sensors

(I) Technical challenges

- High frequency band measurement: As wireless communication technology develops towards high frequency bands such as millimeter waves, RF power sensors need to have higher measurement accuracy and stability.

- Wide dynamic range: In some application scenarios, the power range of RF signals may be very wide, which puts higher requirements on the dynamic range of RF power sensors.

- Anti-interference ability: In complex electromagnetic environments, RF power sensors need to have stronger anti-interference ability to ensure the accuracy of measurement results.

(II) Future Outlook

- Technological Innovation: With the continuous development of new materials, new processes and new technologies, RF power sensors are expected to achieve higher measurement accuracy, wider frequency range and smaller size.

- Intelligent Application: With the popularization of Internet of Things and artificial intelligence technology, RF power sensors will pay more attention to intelligent applications, such as automatic calibration, remote monitoring and data analysis.

- Integrated Development: In the future, RF power sensors are expected to integrate with other types of sensors and measuring instruments to form a more comprehensive and efficient measurement system.

Summary

RF power sensor is an important measuring instrument with wide applications in wireless communication, RF testing, electronic measurement and other fields.

Suitable for Volkswagen Golf car height sensor liquid level sensor level sensor

Through a detailed introduction to the basic concepts, classification, working principles, key parameters, applications, development trends, selection and use precautions, specific products and application cases, as well as technical challenges and future prospects of RF power sensors, we can have a deeper understanding of the importance and application value of RF power sensors.

In future development, RF power sensors will continue to play an important role in promoting the progress of wireless communication technology and electronic measurement technology.

ABS sensor wheel speed sensor

PDF download

About IoT Cloud Platform

IOT Cloud Platform (blog.iotcloudplatform.com) focuses on IOT solutions, low-altitude economic IoT, WiFi modules, sensors, smart cities, RFID, lora devices, IoT systems, IOT modules, embedded development, photovoltaic solar energy, lithium batteries, chips, IOT circuit boards, Raspberry Pi development and design, Arduino programming, smart home sensors, new energy, semiconductors and other scientific and technological knowledge and products.

In short, the IOT cloud platform is an Internet of Things technology platform, a sensor procurement and WiFi module supply platform.

FAQs

The following are common questions and answers about RF power sensors:

RF power sensor is a device used to measure power in radio frequency (RF) systems. It can accurately measure the power of RF signals, which is crucial for debugging wireless communication systems, quality control in semiconductor manufacturing processes, and performance monitoring of aerospace equipment.

The working principle of RF power sensor is based on the principles of electromagnetic induction or thermoelectric effect in physics. When the RF signal acts on the sensor, it causes changes in its internal physical quantities (such as current, voltage or temperature). The sensor converts these changes into electrical signals and processes them to obtain accurate power measurements.

RF power sensors can be divided into electromagnetic induction type, thermocouple type, thermistor type, etc. according to the working principle; they can be divided into low power sensors, medium power sensors, and high power sensors according to the measurement range; they can be divided into narrowband sensors and broadband sensors according to the frequency response. In addition, there are intelligent power sensors, which incorporate additional functions such as intelligent control and remote monitoring.

When selecting an RF power sensor, you need to consider factors such as measurement requirements (power range, frequency range, accuracy requirements), performance indicators (sensitivity, stability, response time), physical characteristics (size, weight, mounting method), and additional functions and price.

Common causes of damage to RF power sensors include:

Exceeding the power range: The power measured by the sensor exceeds its dynamic range, causing damage to internal components.

Overvoltage: The DC voltage in the signal exceeds the maximum voltage that the sensor can handle, damaging components such as the partition.

Connection problems: Damaged or substandard RF connectors or adapters cause transmission and reflection losses, affecting measurement accuracy and even damaging the sensor.

Environmental factors: Environmental factors such as temperature, humidity, noise, and vibration may affect the performance of the sensor, and long-term exposure to extreme conditions will shorten the service life of the sensor.

To avoid damage to RF power sensors, you can take the following measures:

Understand the signal level: Make sure the measured power is completely within the dynamic range of the sensor.

Use RF limiters: Attenuate power that exceeds the sensor limit.

Protect RF connectors: Use high-quality RF connectors and adapters to avoid damaged or substandard connectors.

Proper grounding: Use the three-core AC power cord provided with the power meter to ensure that the device is properly grounded.

Proper storage: Store the sensor in a clean, dry environment and avoid exposure to extreme conditions.

Yes, RF power sensors need to be calibrated regularly to ensure the accuracy of the measurement results. The calibration cycle depends on the frequency of use of the sensor, environmental conditions, and manufacturer’s recommendations.

RF power sensors can measure multiple types of RF signals, such as continuous wave signals and pulse signals. Different types of sensors may have different measurement characteristics and applicable ranges.

The accuracy of RF power sensors may be affected by many factors, including the performance of the sensor itself (such as sensitivity, stability), the measurement environment (such as temperature and humidity, noise and vibration), the characteristics of the measured signal (such as frequency, power level), and the test method (such as connection method, calibration accuracy).

RF power sensors are widely used in the field of wireless communications, including base station testing, antenna calibration, signal source verification, power amplifier testing, etc. By accurately measuring the power of RF signals, sensors help ensure the normal operation and performance optimization of wireless communication systems.