What is NTC Temperature Sensor?

NTC temperature sensor, full name Negative Temperature Coefficient Sensor, is a temperature detection element based on thermistor effect.

It uses the characteristic that the resistance value of thermistor changes with temperature to convert temperature information into electrical signals, thereby realizing the measurement and control of temperature.

NTC temperature sensor circuit design

The following is a detailed introduction to NTC temperature sensor technology:

Working principle

The working principle of NTC temperature sensor is based on thermistor effect, that is, the resistivity of the material changes with the change of temperature. NTC thermistor is a resistor with negative temperature coefficient, and its resistance value decreases with the increase of temperature, and vice versa.

This characteristic enables NTC thermistor to sense the change of temperature and convert it into the change of resistance value. Specifically, when the ambient temperature changes, the resistance value of NTC thermistor will change accordingly. By measuring the resistance value of NTC thermistor, the current temperature information can be indirectly obtained.

Since there is a certain functional relationship between the resistance value and temperature of the NTC thermistor (usually a negative exponential relationship), the resistance value can be converted into a temperature value by consulting the resistance-temperature characteristic curve or using the corresponding algorithm.

NTC Temperature Sensor PCB Manufacturing Factory

Structural composition

NTC temperature sensors usually consist of the following parts:

1. Thermistor:

The core component of the NTC temperature sensor, made of temperature-sensitive materials, is usually a mixture of metal oxides such as manganese, cobalt, nickel and copper, and has semiconductor properties. These metal oxides are sintered into a dense ceramic body at high temperature to form a thermistor.

2. Housing:

Used to protect the thermistor and lead wires from the influence of the external environment. The housing material can be plastic, metal or resin, etc., depending on the application environment and requirements.

3. Lead wire:

Used to connect the thermistor and the measurement circuit, usually nickel-copper alloy or copper wire. The quality of the lead wire directly affects the stability and accuracy of the NTC sensor.

4. Terminal connector:

Used to connect the NTC sensor to the external circuit for easy installation and use.

Features and advantages

1. High sensitivity:

The resistance value of the NTC temperature sensor is extremely sensitive to changes in temperature, and can accurately sense small temperature changes.

2. Fast response speed:

Due to the material properties of thermistors, the NTC temperature sensor responds very quickly to temperature changes and is suitable for occasions that require rapid temperature control.

3. Small size:

The size of the NTC temperature sensor is relatively small, making it easy to use in space-constrained occasions, such as portable devices, small household appliances, etc.

4. High accuracy:

Through proper calibration and compensation measures, the NTC temperature sensor can achieve high measurement accuracy to meet various application requirements.

5. Good stability:

The chemical and physical properties of the NTC temperature sensor are stable, not easily affected by environmental factors, and can work stably for a long time.

6. Low cost:

NTC temperature sensors have low manufacturing costs, and the raw materials are widely available and low cost, while the production process is relatively simple.

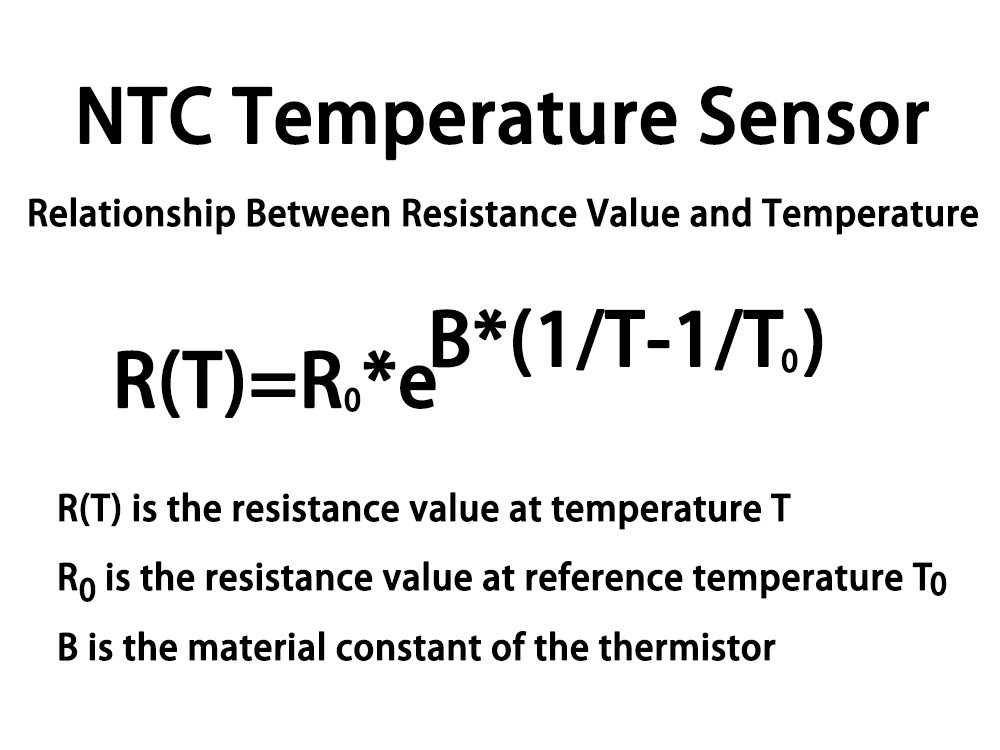

Resistance-temperature characteristics

The relationship between the resistance value and temperature of NTC temperature sensors is usually nonlinear, which can be approximated by the following formula:

R(T)=R0⋅eB⋅(1/T−1/T0)

Relationship between NTC temperature sensor resistance and temperature

Wherein, R(T) is the resistance value at temperature T, R0 is the resistance value at reference temperature T0, and B is the material constant of the thermistor, which is related to the type of material and manufacturing process.

In order to more accurately describe the resistance-temperature characteristics of NTC temperature sensors, the resistance-temperature characteristic curve is usually obtained by experimental measurement and described in the form of a mathematical function. In practical applications, the resistance value can be converted to the temperature value by consulting the resistance-temperature characteristic curve or using the corresponding algorithm.

Application scenarios

Because NTC temperature sensors have the advantages of high sensitivity, fast response speed, small size, high precision, good stability and low cost, they are widely used in various fields:

1. Home appliance field:

Such as air conditioners, refrigerators, washing machines, water heaters, water dispensers and other home appliances, used for temperature measurement and control to ensure the normal operation of the equipment.

2. Automotive field:

Such as temperature measurement and control of automobile engines, cooling systems, air conditioning systems, etc., to improve the performance and safety of automobiles.

3. Medical field:

Such as digital thermometers, incubators, skin sensors, catheters, dialysis equipment and respirators and other medical equipment, used to monitor physiological parameters such as temperature, blood flow or air flow.

4. Industrial field:

Such as industrial automation, temperature compensation, surge current suppression and other occasions, to improve production efficiency and product quality.

5. New energy and energy storage fields:

Such as battery management of energy storage systems, charging systems of new energy vehicles, water cooling systems of power batteries, etc., to ensure the safety and performance of batteries.

6. Other fields:

Such as in consumer electronic products such as smart toilets and electric blankets, used for temperature measurement and control to improve the comfort and safety of products.

Selection and precautions

When selecting an NTC temperature sensor, you need to consider the following factors:

- Measurement range: Select the appropriate temperature measurement range according to application requirements. The measurement range of NTC temperature sensors is usually between -50℃ and +150℃, but there are also special models that can measure higher or lower temperatures.

- Accuracy requirements: Select the appropriate measurement accuracy according to application requirements. The measurement accuracy of NTC temperature sensors is usually between ±0.5℃ and ±2℃, but there are also high-precision models that can reach ±0.1℃.

- Response time: Select the appropriate response time according to application requirements. The response time of NTC temperature sensors is usually between a few milliseconds and tens of milliseconds.

- Package form: Select the appropriate package form according to the installation environment and space. The package forms of NTC temperature sensors include metal shell, plastic shell, resin package, etc.

- Stability and life: Select NTC temperature sensors with good long-term stability and long service life to ensure long-term reliable operation of the equipment.

When using NTC temperature sensors, you also need to pay attention to the following points:

- Temperature compensation: Due to the nonlinear relationship between the resistance and temperature of the NTC temperature sensor, temperature compensation is required in high-precision measurement. Usually, compensation can be made by referring to the resistance-temperature characteristic curve or using the corresponding algorithm.

- Self-heating effect: When current passes through the NTC temperature sensor, self-heating effect will occur, affecting the measurement accuracy. Therefore, when using it, you need to pay attention to the control of the current size and measurement time.

- Installation and wiring: During installation and wiring, you need to pay attention to avoid the influence of factors such as mechanical stress, electromagnetic interference and thermal interference to ensure the accuracy of the measurement.

What is an NTC Temperature Sensor?

Development Trend

With the rapid development of technologies such as the Internet of Things and intelligent manufacturing, the application of NTC temperature sensors in various fields will become more extensive. In the future, NTC temperature sensors will develop in the direction of smaller size, higher precision, higher stability, and more intelligence. At the same time, with the continuous advancement of materials science and electronic technology, the performance of NTC temperature sensors will continue to improve, providing more reliable and efficient temperature measurement and control solutions for the development of various fields.

Technical details and in-depth analysis

Materials and preparation of thermistors

- NTC thermistors are usually made of a mixture of metal oxides such as manganese, cobalt, nickel and copper, which are sintered into a dense ceramic body at high temperature. The change in the resistivity of the ceramic body with temperature is the basis of the NTC effect.

- During the preparation process, it is necessary to accurately control parameters such as the ratio of raw materials, mixing uniformity, molding pressure and sintering temperature to obtain a thermistor with stable performance.

Measurement of resistance-temperature characteristic curve

- The resistance-temperature characteristic curve is a mathematical function that describes the relationship between the resistance value and temperature of the NTC temperature sensor. It is usually obtained through experimental measurement, and the temperature change rate and measurement accuracy need to be strictly controlled during the measurement process.

- In practical applications, high-precision temperature sources and resistance measuring instruments can be used to measure the resistance-temperature characteristic curve, and the measurement results can be stored in the form of mathematical functions or applied to the temperature measurement algorithm.

Temperature compensation algorithm

- Due to the nonlinear relationship between the resistance and temperature of the NTC temperature sensor, temperature compensation is required in high-precision measurement. The temperature compensation algorithm is usually based on the resistance-temperature characteristic curve, and the resistance value is converted into a temperature value through mathematical operations.

- Common temperature compensation algorithms include first-order approximation, polynomial fitting, lookup table method, and Steinhart-Hart formula. Among them, the Steinhart-Hart formula is widely regarded as the best thermistor approximation to date, with high accuracy over a wide temperature range.

Influence and suppression of self-heating effect

- When current passes through the NTC temperature sensor, self-heating effect will occur, resulting in changes in resistance value and measurement errors. The degree of influence of the self-heating effect is related to factors such as the magnitude of the current, the material and size of the thermistor.

- In order to suppress the influence of self-heating effect, measures such as reducing the measurement current, shortening the measurement time, and optimizing the structure and material of thermistor can be taken.

Selection and influence of packaging form

- The packaging form of NTC temperature sensor has an important influence on its performance and application scenarios. Metal shell packaging has good heat dissipation performance and mechanical strength, and is suitable for harsh environments such as high temperature and high humidity; plastic shell packaging has the advantages of low cost, easy processing and installation, and is suitable for general industrial occasions; resin packaging has better insulation and moisture resistance, and is suitable for occasions with high insulation requirements.

- When choosing the packaging form, it is necessary to comprehensively consider factors such as application environment, installation space, and cost.

Case Analysis and Application Examples

Case 1: Temperature Control in Home Appliances

NTC temperature sensors are widely used for temperature measurement and control in home appliances such as air conditioners and refrigerators. For example, in air conditioners, NTC temperature sensors are installed in key parts such as evaporators and condensers to monitor the temperature changes of refrigerants, and adjust the operating status of the compressor and the speed of the fan according to the monitoring results to achieve precise temperature control.

In this case, the high precision and fast response characteristics of the NTC temperature sensor played an important role. It can sense temperature changes in real time and accurately convert temperature information into electrical signals to provide reliable feedback for the air conditioning control system. At the same time, due to its small size and low cost, it also facilitates the installation and maintenance of the equipment.

Case 2: Temperature Monitoring in the Automobile Field

In the field of automobile manufacturing, NTC temperature sensors play a vital role, especially in engine temperature detection, air conditioning system control, and battery management. The following will elaborate on the application and importance of NTC temperature sensors in the automotive field.

- Engine temperature detection

The engine is the heart of the car, and its operating temperature has a vital impact on the performance and life of the car. In order to ensure the normal operation of the engine, it is necessary to monitor the temperature changes of the engine in real time. NTC temperature sensors are widely used in engine temperature detection due to their high precision, fast response and small size.

In the engine cooling system, NTC temperature sensors are usually installed at the radiator outlet or on the engine block to monitor the temperature changes of the coolant or engine block. When the temperature exceeds the set value, the sensor will immediately sound an alarm and adjust the speed of the cooling fan and the working state of the water pump through the control system to ensure that the engine temperature remains within a suitable range. This not only improves the working efficiency of the engine, but also extends the service life of the engine.

- Air conditioning system control

The main function of the automobile air conditioning system is to adjust the temperature and humidity in the car to provide passengers with a comfortable riding environment. NTC temperature sensors also play an important role in the air conditioning system.

In the air conditioning system, NTC temperature sensors are usually installed in key parts such as evaporators and condensers. The sensor transmits temperature information to the air conditioning system control unit by monitoring the changes in the evaporator surface temperature and the temperature in the car. The control unit automatically adjusts the operating status of the compressor, the speed of the fan, and the opening degree of the air outlet according to the received temperature signal to achieve precise control of the temperature and humidity in the car.

- Battery Management

With the popularity of electric vehicles and hybrid vehicles, the importance of battery management systems has become increasingly prominent. One of the core functions of the battery management system is to monitor the temperature changes of the battery to prevent the battery from overheating or overcooling and affecting the battery performance and life.

NTC temperature sensors are widely used in battery management systems due to their high precision, stability and reliability. The sensors are installed in various key parts of the battery pack to monitor the temperature changes of battery cells and battery packs. When the temperature exceeds the set value, the sensor will immediately sound an alarm and adjust the battery charging and discharging power and the speed of the cooling fan through the control system to ensure that the battery temperature remains within a suitable range. This not only improves the performance and life of the battery, but also ensures the safe operation of electric vehicles and hybrid vehicles.

Case 3: Temperature monitoring in the medical field

In the medical field, NTC temperature sensors are also widely used in temperature monitoring of various medical equipment. The following will introduce its application scenarios in the medical field and its importance.

- Body temperature monitoring

Body temperature is one of the important indicators reflecting human health status. In the medical field, NTC temperature sensors are widely used in body temperature monitoring. For example, digital thermometers use NTC temperature sensors as core temperature measuring elements. The sensor monitors the temperature changes on the surface of the human body and transmits the temperature information to the display unit to achieve accurate measurement of body temperature.

Compared with traditional mercury thermometers, digital thermometers using NTC temperature sensors have the advantages of fast measurement speed, high accuracy, and easy reading. At the same time, due to its small size and low cost, it also facilitates the manufacture and popularization of thermometers.

- Temperature control of medical equipment

In medical equipment, many devices require precise temperature control. For example, incubators, thermostats and other equipment need to maintain a constant temperature environment to ensure the accuracy and reliability of experimental results. NTC temperature sensors are widely used in the temperature control of these devices due to their high accuracy, fast response and small size.

The sensor is installed in the heating or cooling system of the equipment to monitor the temperature changes inside the equipment. When the temperature deviates from the set value, the sensor will immediately sound an alarm and adjust the heating or cooling power through the control system to ensure that the internal temperature of the equipment remains within a suitable range. This not only improves the performance and reliability of the equipment, but also ensures the accuracy and reliability of the experimental results.

Case 4: Temperature monitoring and control in the industrial field

In the industrial field, NTC temperature sensors are also widely used in temperature monitoring and control of various industrial equipment. The following will introduce its application scenarios and importance in the industrial field.

- Temperature compensation

In industrial measurement and automatic control systems, many devices need to accurately measure and compensate for temperature. For example, in electronic scales, pressure sensors and other devices, temperature compensation is required because temperature changes will affect the measurement results. NTC temperature sensors are widely used in temperature compensation of these devices due to their high precision, stability and reliability.

The sensor is installed in the measuring unit or signal processing unit of the device to monitor the temperature changes inside the device. When the temperature changes, the sensor immediately transmits the temperature information to the control system. The control system automatically adjusts the gain or offset of the measuring unit according to the received temperature signal to achieve accurate compensation of the measurement results.

- Industrial Automation Control

In industrial automation control systems, NTC temperature sensors are widely used in temperature monitoring and control of various industrial equipment. For example, in heat treatment furnaces, dryers, injection molding machines and other equipment, the temperature needs to be precisely controlled to ensure product quality and production efficiency.

The sensor is installed in the heating or cooling system of the equipment to monitor temperature changes inside the equipment. When the temperature deviates from the set value, the sensor will immediately sound an alarm and adjust the heating or cooling power through the control system to ensure that the temperature inside the equipment remains within a suitable range. This not only improves the performance and reliability of the equipment, but also ensures the quality and production efficiency of the product.

Waterproof NTC Temperature Sensor 10K/B3950

Development Trend of NTC Temperature Sensors

With the continuous advancement of science and technology and the continuous expansion of application fields, NTC temperature sensors are moving towards smaller, higher precision, higher stability, and more intelligent directions. The following will introduce the development trend and prospects of NTC temperature sensors.

1. Miniaturization and Integration

With the continuous miniaturization and integration of electronic equipment, NTC temperature sensors are also moving towards smaller and more integrated directions. For example, NTC temperature sensors manufactured using micro-nano technology and surface mount technology are smaller in size, lighter in weight, and easier to install, which can meet the needs of various miniaturized electronic devices.

2. High precision and stability

With the continuous expansion of application areas and the increasing requirements for measurement accuracy, NTC temperature sensors are also developing towards higher precision and higher stability. For example, NTC temperature sensors manufactured using high-precision materials and advanced manufacturing processes have significantly improved their measurement accuracy and stability, which can meet the needs of various high-precision measurement and control.

3. Intelligence and networking

With the continuous development of the Internet of Things and artificial intelligence technologies, NTC temperature sensors are also developing towards a more intelligent and networked direction. For example, NTC temperature sensors using smart sensors and wireless communication technology can realize functions such as remote monitoring, data sharing and intelligent early warning, providing more convenient and efficient solutions for temperature monitoring and control.

4. Environmental protection and sustainability

With the increasing global attention to environmental protection and sustainability, NTC temperature sensors are also developing towards a more environmentally friendly and sustainable direction. For example, NTC temperature sensors that use environmentally friendly materials and energy-saving technologies can reduce energy consumption and pollution in the production process, meeting the requirements of sustainable development.

Selection and application recommendations of NTC temperature sensors

NTC temperature sensor – thermistor pt100 temperature sensor temperature probe

When selecting and applying NTC temperature sensors, multiple factors need to be considered to ensure that they can meet application requirements. The following will introduce the selection and application recommendations of NTC temperature sensors.

1. Measurement range and accuracy

When selecting an NTC temperature sensor, its measurement range and accuracy need to be determined according to application requirements. For example, when high-precision body temperature monitoring is required in the medical field, a sensor with a higher measurement range and accuracy should be selected; when a wide temperature range measurement is required in the industrial field, a sensor with a wider measurement range should be selected.

2. Response time and stability

When selecting an NTC temperature sensor, its response time and stability also need to be considered. For example, in applications that require fast temperature response (such as automobile engine temperature detection), a sensor with a shorter response time should be selected; in applications that require long-term stable operation (such as medical equipment temperature control), a sensor with better stability should be selected.

3. Packaging form and installation method

When selecting an NTC temperature sensor, you also need to consider its packaging form and installation method. For example, in applications that require moisture and dust resistance (such as automotive air conditioning system control), a packaging form with good moisture and dust resistance should be selected; in applications that require convenient installation and disassembly (such as industrial equipment temperature compensation), an installation method that is easy to install and disassemble should be selected.

4. Cost and cost performance

When selecting an NTC temperature sensor, you also need to consider its cost and cost performance. For example, in applications that require high precision and high stability (such as medical equipment temperature control), although the cost of the sensor is high, considering its impact on equipment performance and reliability, its cost performance is still high; in applications that require low cost (such as general industrial measurement), a sensor with low cost and that meets application requirements should be selected.

Summary and Outlook

As a temperature detection element based on the thermal effect, the NTC temperature sensor has the advantages of high sensitivity, fast response speed, small size, high precision, good stability and low cost, and is widely used in home appliances, automobiles, medical care, industry and other fields.

With the continuous advancement of science and technology and the continuous expansion of application fields, NTC temperature sensors are developing towards smaller size, higher precision, higher stability, and more intelligent directions.

In the future, NTC temperature sensors will continue to play an important role in various fields, providing more convenient and efficient temperature monitoring and control solutions for people’s lives and work. At the same time, with the continuous development of technologies such as the Internet of Things and artificial intelligence, NTC temperature sensors will also be deeply integrated with these technologies to achieve more intelligent and automated temperature management.

For example, by integrating the Internet of Things technology, NTC temperature sensors can upload real-time monitored temperature data to the cloud platform for big data analysis and intelligent early warning; by integrating artificial intelligence technology, the system can automatically adjust the temperature control strategy according to historical data and the current environment to achieve more refined temperature management.

In short, as an important temperature detection component, NTC temperature sensors will continue to play an important role in the future and contribute more to the development of various fields.

PDF download

About IoT Cloud Platform

IOT Cloud Platform (blog.iotcloudplatform.com) focuses on IOT solutions, low-altitude economic IoT, WiFi modules, sensors, smart home sensors, smart cities, RFID, lora devices, IoT systems, IOT modules, embedded development, photovoltaic solar energy, lithium batteries, chips, IOT circuit boards, Raspberry Pi development and design, Arduino programming, new energy, semiconductors and other scientific and technological knowledge and products.

FAQs

Here are some frequently asked questions and answers about NTC temperature sensors:

NTC (Negative Temperature Coefficient) temperature sensor is a negative temperature coefficient thermistor whose resistance decreases as the temperature increases. It is widely used in various occasions that require temperature measurement, such as air conditioners, refrigerators, wall-mounted boilers, charging piles, etc.

Common faults of NTC temperature sensors include increased resistance, open circuit, resistance change due to moisture and mildew, short circuit, poor contact between plug and socket, or leakage.

The increase in resistance of NTC temperature sensors may be caused by sensor aging, component damage, or long-term operation in a high temperature environment.

Open circuit means that the internal circuit of the sensor is disconnected, resulting in infinite resistance. This may be caused by damage to the internal components of the sensor, broken circuits, or poor welding.

If the NTC temperature sensor is damp and mildewed, its resistance value will change, affecting the accuracy of measurement. In addition, a humid environment may also accelerate the aging process of the sensor.

A short circuit will make the resistance value of the sensor very small, even close to zero. This will cause inaccurate temperature measurements and may even damage the circuit connected to it.

If the plug and socket are not in good contact, check whether the plug and socket are corroded, oxidized or loose. If necessary, clean the plug and socket, or replace them with new ones.

You can determine whether it is damaged by measuring the resistance value of the sensor. If the resistance value exceeds the normal range, or the law of resistance value changing with temperature does not match the nominal value, it means that the sensor may be damaged.

If the NTC temperature sensor is damaged, a new sensor should be replaced in time. When replacing, a sensor with the same model and specification as the original sensor should be selected to ensure the accuracy of measurement and the stability of the system.

Methods to prevent NTC temperature sensor failure include: regularly checking and cleaning the sensor, avoiding long-term exposure of the sensor to high temperature, humidity or corrosive environment; ensuring that the sensor is installed in the correct position to avoid mechanical shock or vibration; performing regular calibration and maintenance according to the manufacturer’s recommendations, etc.