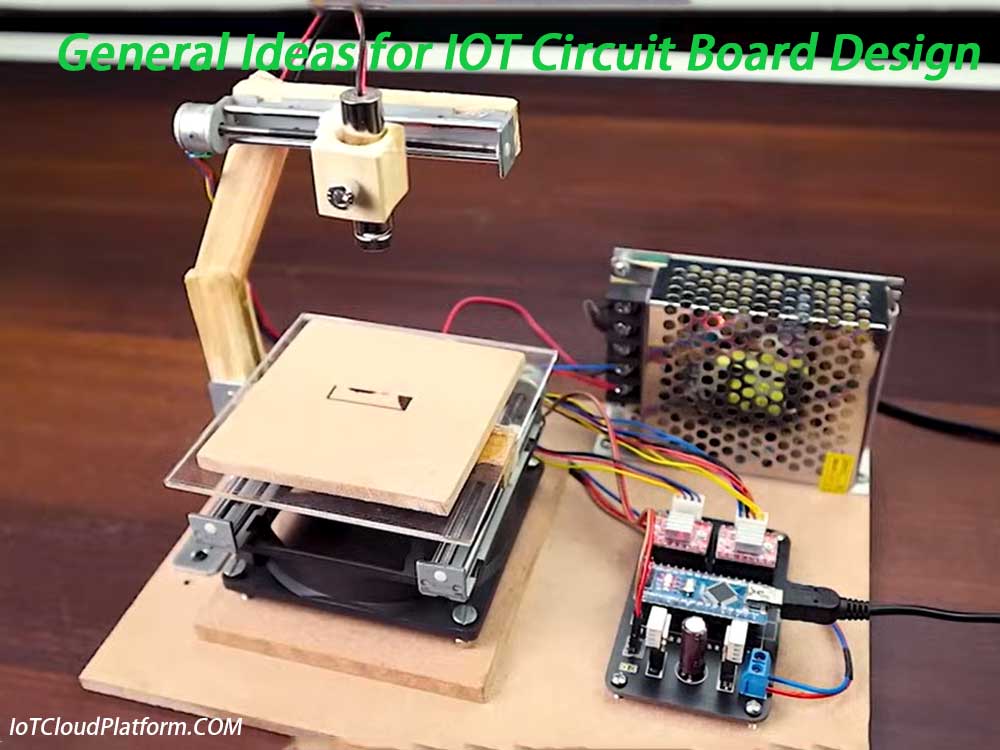

General Ideas for IOT Circuit Board Design

The idea of IOT (Internet of Things) circuit board design is a complex and delicate process, which involves multiple considerations, including hardware design, software design, power management, security, and network communication.

The following is a detailed introduction to the general ideas for IOT circuit board design:

Pre-design preparation

Demand analysis and specification determination

- Demand analysis: Clarify the functional requirements, performance indicators, and usage environment of IOT devices. This includes the type of sensors, actuator types, communication protocols, data processing capabilities, etc. that need to be connected.

- Specification determination: Determine the size, layout, interface, power consumption and other specifications of the circuit board based on the results of the demand analysis.

Selection and procurement

- Component selection: Select suitable microcontrollers (MCU), sensors, actuators, communication modules and other components. The selection of these components should be based on functional requirements, performance parameters, cost, supply channels and other factors.

- Procurement: Purchase the required components and materials based on the selection results.

Hardware Design

Circuit Schematic Design

- Tool Selection: Use professional circuit design software (such as Protel99SE, Altium Designer, etc.) for schematic design.

- Component Placement and Connection: Place the selected components in the schematic and connect them according to the circuit logic. Pay attention to the packaging form, pin assignment, electrical characteristics, etc. of the components.

- Power Supply Design: Design a stable power supply circuit to provide the appropriate voltage and current for the entire circuit board. Consider using high-efficiency power supply ICs and appropriate filtering circuits.

- Communication Interface Design: Design appropriate communication interface circuits, including wired interfaces (such as Ethernet, USB, etc.) and wireless interfaces (such as WiFi, Bluetooth, Zigbee, etc.).

PCB Layout and Wiring

- Layout Design: Design PCB layout according to the circuit schematic. Pay attention to the placement of components, heat dissipation issues, signal interference, etc.

- Wiring Design: Perform PCB wiring design to ensure that the signal line is reasonably routed, of moderate length, and avoids cross interference. Pay attention to the separation and wiring rules of power lines, ground lines, and signal lines.

- Simulation and verification: Use simulation software to perform circuit simulation and signal integrity analysis to verify the correctness and reliability of the design.

Software design

Firmware development

- Programming language selection: Select a suitable programming language (such as C, C++, Python, etc.) according to the MCU model and development environment.

- Firmware architecture: Design a reasonable firmware architecture, including the main program, interrupt service program, task scheduling, etc.

- Function implementation: Write code to implement the functional requirements of the device, including data acquisition, processing, communication, etc.

Driver development

- Sensor and actuator driver: Write driver programs for sensors and actuators to achieve communication and control with the MCU.

- Communication protocol implementation: Implement the selected communication protocol to ensure that the device can communicate with other devices or cloud platforms.

Power management

- Low power design: Use low-power components, optimize circuit design, and reasonably control power supply to reduce the power consumption of the device.

- Power consumption test: Use power consumption test instruments to test the power consumption of the device to verify the low power consumption effect of the design.

Security Design

- Data Encryption: Encrypt the transmitted data to ensure data security.

- Authentication and Authorization: Implement the authentication and authorization mechanism of the device to prevent unauthorized access and control.

- Firewall and Isolation: Build firewall and isolation mechanism to protect the device from network attacks and malware.

Testing and Verification

- Functional Testing: Perform functional testing on the device to ensure that the device can work as expected.

- Performance Testing: Test the performance of the device, including response time, processing speed, communication distance, etc.

- Reliability Testing: Perform long-term operation tests, environmental adaptability tests, etc. to verify the reliability and stability of the device.

Maintenance and Upgrade

- Firmware Upgrade: Design a firmware upgrade mechanism to facilitate maintenance and upgrade of the device.

- Fault Diagnosis: Provide fault diagnosis and troubleshooting methods to facilitate users to solve device failures.

Summary

- Summary: Summarize the entire process of IOT circuit board circuit design, including design ideas, problems encountered and solutions, etc.

- Prospect: Based on market demand and technology development trends, the future of IOT circuit board design is prospected and planned.

The above is the general idea of IOT circuit board design by the Internet of Things Cloud Platform (blog.iotcloudplatform.com).

In the actual Internet of Things PCB design, it is also necessary to flexibly adjust and optimize according to specific needs and conditions.

About IoT Cloud Platform

IoT Cloud Platform (iotcloudplatform.com) is a Chinese IoT advertising and media company that provides professional IoT product promotion and IoT solution promotion for IoT companies around the world. We build overseas brands for IoT companies and enhance their brand influence. We not only have professional IoT technical knowledge, but also excellent IoT SEO optimization experts, providing one-stop Google SEO marketing services for IoT devices, WiFi modules, smart cities and other products.

IoT Circuit Board FAQs

Demand analysis: clarify the functional requirements, performance indicators, environmental adaptability, etc. of IOT devices.

Hardware selection: select appropriate microcontrollers (MCU), sensors, actuators, communication modules, etc. according to the requirements.

Circuit design: design circuit schematics, including power circuits, signal acquisition circuits, processing circuits, communication circuits, etc.

Simulation verification: use circuit simulation software to simulate the circuit and verify the correctness of the design.

PCB layout and wiring: convert the circuit schematic into a PCB layout diagram, and perform wiring design to ensure signal integrity and electromagnetic compatibility.

Test and debugging: make PCB boards, perform welding, testing, and debugging to ensure the normal operation of the equipment.

Select a suitable MCU according to the functional requirements of IOT devices, considering factors such as its processing power, power consumption, peripheral interfaces, and packaging forms.

Consult the MCU data sheet to understand its performance parameters and usage methods.

Consider the supply stability and cost factors of the MCU.

Design a power supply circuit according to the power requirements of the MCU and other components, including voltage conversion, filtering, protection, etc.

Choose a suitable power chip or module to ensure its stable and reliable performance.

When designing the PCB layout of the power circuit, pay attention to the layout of the power line and ground line to avoid electromagnetic interference.

In circuit design, arrange the signal lines reasonably to avoid crosstalk and interference between signal lines.

Use appropriate signal transmission lines and terminal resistors to ensure the stability and integrity of signal transmission.

When laying out and routing the PCB, pay attention to the length and routing method of the signal line to reduce signal loss and reflection.

In circuit design, use appropriate shielding measures, such as metal shielding covers, shielding layers, etc. to reduce electromagnetic radiation and interference.

Reasonably layout the components and lines on the PCB board to avoid the generation and propagation of electromagnetic interference.

Use appropriate filtering components and grounding methods to improve the anti-interference ability of the circuit.