Design Solution of Chicken House Environment Monitoring System Based on Single-chip Microcomputer

The design of chicken house environment monitoring system based on single-chip microcomputer is a complex but crucial project, which is of great significance for improving the growth environment of poultry, reducing the incidence of diseases and improving breeding efficiency.

The following is a detailed solution covering design ideas, hardware composition, software implementation, performance evaluation and other aspects.

Monitoring System Based on Single-chip Microcomputer" class="wp-image-2680" title="Design Solution of Chicken House Environment Monitoring System Based on Single-chip Microcomputer" srcset="https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/Design-Solution-of-Chicken-House-Environment-Monitoring-System-Based-on-Single-chip-Microcomputer.jpg 1000w, https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/Design-Solution-of-Chicken-House-Environment-Monitoring-System-Based-on-Single-chip-Microcomputer-300x225.jpg 300w, https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/Design-Solution-of-Chicken-House-Environment-Monitoring-System-Based-on-Single-chip-Microcomputer-150x113.jpg 150w, https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/Design-Solution-of-Chicken-House-Environment-Monitoring-System-Based-on-Single-chip-Microcomputer-768x576.jpg 768w" sizes="(max-width: 1000px) 100vw, 1000px" />

Monitoring System Based on Single-chip Microcomputer" class="wp-image-2680" title="Design Solution of Chicken House Environment Monitoring System Based on Single-chip Microcomputer" srcset="https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/Design-Solution-of-Chicken-House-Environment-Monitoring-System-Based-on-Single-chip-Microcomputer.jpg 1000w, https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/Design-Solution-of-Chicken-House-Environment-Monitoring-System-Based-on-Single-chip-Microcomputer-300x225.jpg 300w, https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/Design-Solution-of-Chicken-House-Environment-Monitoring-System-Based-on-Single-chip-Microcomputer-150x113.jpg 150w, https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/Design-Solution-of-Chicken-House-Environment-Monitoring-System-Based-on-Single-chip-Microcomputer-768x576.jpg 768w" sizes="(max-width: 1000px) 100vw, 1000px" />Design Solution of Chicken House Environment Monitoring System Based on Single-chip Microcomputer

Introduction

With the rapid development of modern breeding industry, the impact of chicken house environment on poultry growth and health has been increasingly valued. An efficient and intelligent chicken house environment monitoring system is essential for improving the yield and quality of poultry. The chicken house environment monitoring system based on single-chip microcomputer can monitor and adjust the environmental parameters in the chicken house in real time, providing a comfortable and healthy growth environment for poultry.

System design principle

The chicken house environment monitoring system based on single-chip microcomputer uses single-chip microcomputer as the core control unit, combined with sensor technology, actuator technology and communication technology, to realize automatic monitoring and control of chicken house temperature, humidity, light, harmful gas concentration and other environments. The system design aims to provide an intelligent, efficient and stable chicken house environment to provide a comfortable growth space for poultry.

System composition

1. Hardware composition

The hardware part mainly includes MCU control unit, sensor module, actuator module, communication module and power module, etc.

- MCU control unit: As the core of the whole system, it is responsible for receiving sensor data, processing data and issuing control instructions. Commonly used MCUs include STC series, PIC series, STM32 series, etc.

- Sensor module: Including temperature sensor, humidity sensor, light sensor, harmful gas concentration sensor, etc., used to monitor the environmental parameters of the chicken house in real time. These sensors can accurately and quickly collect environmental data and provide a basis for the control of the MCU.

- Actuator module: Including heater, humidifier, ventilation equipment, lighting equipment, etc., according to the instructions issued by the MCU to perform corresponding actions and adjust the chicken house environment.

- Communication module: Used to realize the communication between the system and the host computer or mobile phone APP, so that users can remotely monitor and control the chicken house environment. Common communication methods include Bluetooth, Wi-Fi, Zigbee, etc.

- Power module: Provides stable power supply for the entire system to ensure stable operation of the system in harsh environments.

2. Software design

The software part mainly includes the program design of the MCU and the interface design of the host computer or mobile phone APP.

- MCU program design: It is written in programming languages such as C language to realize the functions of collecting, processing and transmitting sensor data, controlling actuators and communicating with other devices. The program needs to be continuously optimized and improved to improve the stability and reliability of the system.

- Host computer or mobile phone APP interface design: Design a friendly user interface to facilitate users to set and view chicken house environmental parameters, receive alarm information, etc. The interface needs to be intuitive and easy to operate.

System function

1. Environmental monitoring:

Real-time monitoring of environmental parameters such as temperature, humidity, light, and harmful gas concentration in the chicken house.

2. Automatic control:

According to the preset control algorithm and environmental parameters, the actuator modules such as heaters, humidifiers, ventilation equipment, and lighting equipment are automatically controlled to make the chicken house environment reach the preset optimal state.

3. Alarm function:

When the chicken house environmental parameters exceed the set range, the system will issue an alarm message to remind the user to deal with it in time.

4. Remote monitoring:

Through the communication module, users can remotely monitor the chicken house environmental parameters and equipment status in real time.

5. Data recording and analysis:

The system can record and store historical data, which is convenient for users to analyze data and optimize breeding strategies.

Hardware design details

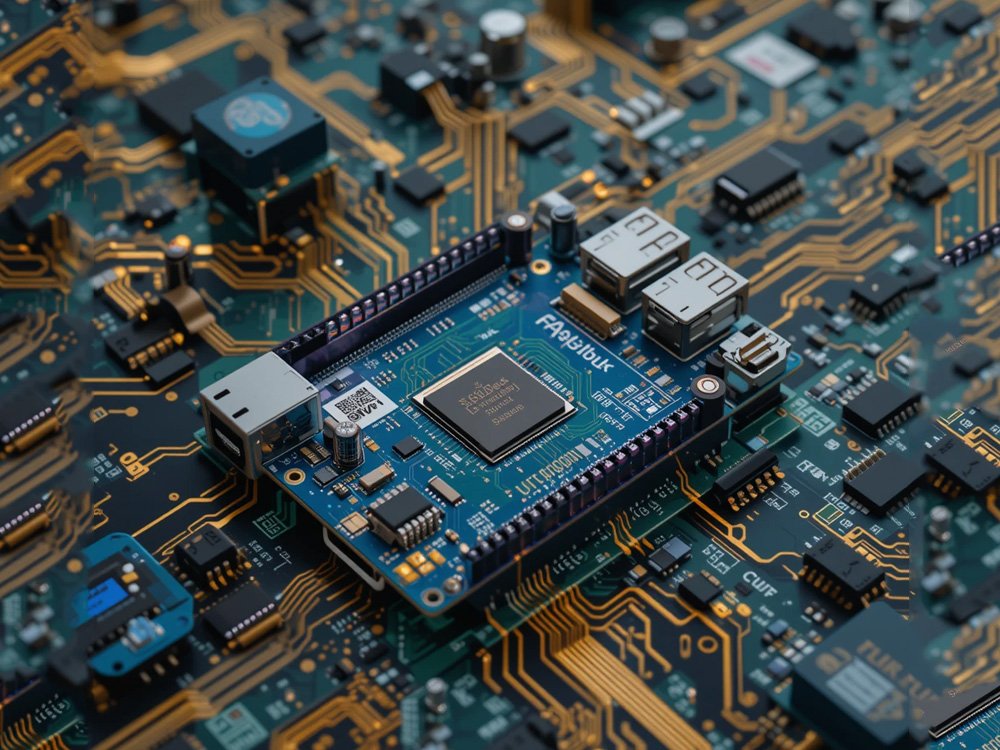

Single chip microcomputer used in chicken house environment monitoring IOT system

1. MCU selection

As the core of the entire system, the performance of the MCU directly determines whether the system can achieve high-efficiency control. Therefore, MCU products with fast running speed, strong processing power, stability and reliability should be selected. For example, STC89C52, STM32F103C8T6, etc. are all commonly used MCU models.

2. Sensor selection and layout

Sensors are the key part of the system to obtain chicken house environmental information. According to the actual needs of chicken house environmental control, you can choose temperature sensors (such as DHT11), humidity sensors, light sensors (such as photoresistors), harmful gas concentration sensors (such as MQ-2), etc. The layout of sensors needs to take into account factors such as signal transmission distance, interference factors, and measurement accuracy.

3. Actuator selection and control

Actuators are the means by which the system controls the chicken house environment. According to actual needs, you can choose equipment such as heaters, ventilators, humidifiers, and lighting. The control of actuators needs to be precise and fast to ensure the stability of the chicken house environment. For example, the control signal of the microcontroller is converted into the action signal of the actuator through the relay module.

4. Communication module design

The communication module is used to realize the communication between the system and the host computer or mobile phone APP. According to actual needs, you can choose communication methods such as Bluetooth, Wi-Fi, and Zigbee. The design of the communication module needs to take into account factors such as data transmission rate, stability, and power consumption.

5. Power module design

The power module provides a stable power supply for the entire system. When designing, factors such as the system’s power consumption, voltage range, and power supply stability need to be considered. Appropriate power chips and voltage regulator circuits can be selected to ensure the stable operation of the system in harsh environments.

Software design details

1. Data acquisition and processing

The sensor module collects the chicken house environmental parameters in real time, and after processing by the single-chip microcomputer, the data is transmitted to the host computer or mobile phone APP. Data acquisition needs to be accurate and fast, and the processing algorithm needs to be efficient and stable.

2. Control algorithm design

According to the collected environmental parameters, the corresponding control instructions are calculated through the preset control algorithm and sent to the actuator module for execution. The design of the control algorithm needs to take into account factors such as the real-time, stability, and accuracy of the system. Advanced control strategies such as fuzzy control algorithms and neural network control algorithms can be used.

3. User interface design

Design a friendly user interface to facilitate users to set and view chicken house environmental parameters, receive alarm information, etc. The interface design needs to be intuitive and easy to operate. Graphical interface design can be used to improve user experience.

4. Security and protection measures

The system should have electrical safety protection measures such as lightning protection and overvoltage protection to prevent system damage caused by sudden weather changes or equipment failures. At the same time, the system should have data backup and recovery functions to prevent data loss due to unexpected situations. For possible network attacks or malicious sabotage, the system should have corresponding security protection measures, such as setting access rights and encrypting communications.

IoT Solutions" class="wp-image-2689" srcset="https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/MCU-IoT-Solution.jpg 1000w, https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/MCU-IoT-Solution-300x225.jpg 300w, https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/MCU-IoT-Solution-150x113.jpg 150w, https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/MCU-IoT-Solution-768x576.jpg 768w" sizes="(max-width: 1000px) 100vw, 1000px" />

IoT Solutions" class="wp-image-2689" srcset="https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/MCU-IoT-Solution.jpg 1000w, https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/MCU-IoT-Solution-300x225.jpg 300w, https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/MCU-IoT-Solution-150x113.jpg 150w, https://blog.iotcloudplatform.com/wp-content/uploads/2025/02/MCU-IoT-Solution-768x576.jpg 768w" sizes="(max-width: 1000px) 100vw, 1000px" />MCU IoT Solutions

System performance evaluation and optimization

Performance evaluation is an important part of system design. By evaluating the stability, reliability, real-time performance and other aspects of the system, we can understand the actual performance of the system and make corresponding optimizations and improvements.

1. Stability evaluation

The stability of the system is the key to ensuring the long-term stable operation of the system. During the evaluation process, the system needs to be tested for a long time to observe its performance in actual use. The stability and reliability of the system can be tested by simulating various environmental conditions and abnormal situations.

2. Reliability evaluation

The reliability of the system refers to the ability of the system to work normally and achieve the expected results under various conditions. During the evaluation process, factors such as the hardware and software design of the system, the accuracy and stability of the sensor, and the response speed and accuracy of the actuator need to be considered. Reliability evaluation can be carried out through comparative testing, fault simulation, etc.

3. Real-time evaluation

The real-time performance of the system refers to the ability of the system to respond to environmental changes in a timely manner and make corresponding adjustments. During the evaluation process, it is necessary to test the system’s response speed and adjustment accuracy to changes in environmental parameters. The real-time performance and accuracy of the system can be tested by setting different thresholds and alarm conditions.

4. Optimization and improvement

According to the results of the performance evaluation, the system can be optimized and improved accordingly. For example, optimize the control algorithm, improve the speed of data acquisition and processing, enhance the stability and reliability of the system, etc. At the same time, new functions can be added or system performance can be improved according to user needs and technological development.

Actual application and effect

The chicken house environment monitoring system based on single-chip microcomputer has achieved remarkable results in actual application. First of all, the system can monitor and automatically control the chicken house environmental parameters in real time, so that poultry is in a comfortable growth environment, which effectively improves the growth rate and survival rate of poultry. Secondly, through the remote monitoring function, users can understand the situation of the chicken house at any time and make corresponding treatments, which improves management efficiency. In addition, the system also has alarm function and data recording and analysis function, which is convenient for users to find problems and make improvements in time.

Future development trends and prospects

With the development of Internet of Things technology, the chicken house environment monitoring system will be more intelligent and automated. In the future, we can combine the system with cloud computing, big data and other technologies to achieve remote monitoring and intelligent management, and provide more efficient and intelligent solutions for agricultural production. At the same time, we also need to continuously explore new technical means and methods to improve the performance and reliability of the system and provide better services for agricultural production.

Conclusion

The chicken house environment monitoring system based on single-chip microcomputer is an efficient and intelligent control system that can monitor and adjust the environmental parameters in the chicken house in real time and improve the growth rate and survival rate of poultry.

This paper introduces the design principle, hardware composition, software implementation and performance evaluation of the system in detail, providing a useful reference for practical application.

In future development, we will continue to optimize the system design, improve the stability and reliability of the system, and provide better support for agricultural production.

Single chip microcomputer chicken house environment monitoring system design solution PDF download

About IoT Cloud Platform

IOT Cloud Platform (blog.iotcloudplatform.com) focuses on IOT solutions, sensors, smart homes, smart cities, IoT design, RFID, lora devices, IoT systems, IoT programming, security IoT, industrial IoT, military IoT, best IoT projects, IOT modules, embedded development, IOT circuit boards, Raspberry Pi development and design, Arduino programming, programming languages, new energy, semiconductors, smart hardware, photovoltaic solar energy, lithium batteries, chips and other scientific and technological knowledge and products.

FAQs

The following are frequently asked questions and answers about the design of a chicken house environmental monitoring system based on a single-chip microcomputer:

The chicken house environment monitoring system based on the single-chip microcomputer mainly includes hardware and software parts. The hardware part includes sensors (such as temperature sensors, humidity sensors, light sensors, etc.), actuators (such as heaters, ventilators, sprinklers, etc.), single-chip microcomputer control units and power modules. The software part is the program design of the single-chip microcomputer, including data acquisition, processing, transmission and the issuance of control instructions.

The sensor is the key part of the system to obtain chicken house environmental information. It can monitor the temperature, humidity, light, carbon dioxide concentration and other environmental parameters in the chicken house in real time, and provide a basis for the control of the single-chip microcomputer.

The actuator is the means by which the system controls the chicken house environment. It can adjust the chicken house environment according to the instructions of the single-chip microcomputer, such as ventilation, heating, cooling, lighting, etc.

The MCU control unit is the core of the entire system, responsible for receiving environmental information transmitted by sensors, controlling actuators according to preset logic, and also processing data collection, transmission, and communication with other devices.

The system can communicate with the host computer or mobile phone APP through communication modules (such as Bluetooth modules, Wi-Fi modules, etc.). Users can remotely monitor chicken house environmental parameters and equipment status through mobile phones or computers, and even control ventilation and lighting equipment through mobile phone APP.

The system can ensure the accuracy and stability of data by selecting high-precision and high-stability sensors and actuators, and using advanced control algorithms and data processing technologies. At the same time, the system also needs to be calibrated and maintained regularly to ensure its long-term stable operation.

The system can set an alarm function. When the chicken house environmental parameters exceed the set range, the system will issue an alarm message to remind users to deal with it in time. In addition, the system can also adopt redundant design, such as backup power supply, backup actuator, etc., to prevent losses when the system fails.

When designing the chicken house environment monitoring system, multiple factors need to be considered, including the stability, reliability, real-time, accuracy, cost and user-friendliness of the system. At the same time, customized design is also required according to the actual environment and needs of the chicken house to meet the needs of different users.

The system can analyze and learn historical data by introducing intelligent control strategies such as machine learning and expert systems, predict the changing trend of the chicken house environment in the future, and adjust the equipment in advance to adapt to environmental changes. In addition, the system can also combine technologies such as the Internet of Things and cloud computing to achieve remote monitoring and intelligent management, providing more efficient and intelligent solutions for agricultural production.

The performance of the chicken house environment monitoring system can be evaluated from multiple aspects, including the stability, reliability, real-time, accuracy, user-friendliness and cost-effectiveness of the system. During the evaluation process, the system needs to be tested for a long time to observe its performance in actual use, and the system should be continuously improved and optimized based on the test results.

The MCU control unit is the core of the entire system. It is responsible for receiving environmental information transmitted by sensors, such as temperature, humidity, light intensity, carbon dioxide concentration, etc., and processing this information according to the preset logic algorithm, and then issuing control instructions to the actuator to adjust the environmental parameters in the chicken house.

In the chicken house environment monitoring system, commonly used MCUs include STC series, PIC series, etc. These MCUs have the characteristics of high performance, low power consumption, easy programming and expansion, and are suitable for building complex environmental monitoring systems.

MCU control units usually communicate with sensors and actuators through analog or digital interfaces. The sensor converts the collected environmental parameters into electrical signals and transmits them to the microcontroller through the interface; the microcontroller issues control instructions based on these signals and transmits them to the actuator through the interface to adjust the chicken house environment.

The program of the microcontroller control unit is usually written in C language or assembly language. Programmers need to write programs for data collection, processing, transmission and control instruction issuance according to the functional requirements of the system. In the writing process, factors such as program stability, reliability and real-time performance also need to be considered.

In order to ensure the stability and reliability of the system, the microcontroller control unit needs to use hardware circuits and components with strong anti-interference ability and high stability. At the same time, in terms of software design, technical means such as redundant design, error detection and recovery are needed to improve the system’s fault tolerance and anti-interference ability.

The MCU control unit can achieve intelligent control of the chicken house environment by introducing intelligent control algorithms, such as PID control, fuzzy control, etc. These algorithms can automatically adjust the control instructions according to the changing trend of environmental parameters and the preset target values to achieve the best environmental control effect.

The MCU control unit can communicate with other devices through communication modules (such as Bluetooth, Wi-Fi, Zigbee, etc.) to achieve remote monitoring. Users can remotely view the environmental parameters and equipment status of the chicken house through terminal devices such as mobile phone APP and computers, and can send control instructions to the MCU control unit to achieve remote adjustment of the chicken house environment.

When selecting, factors such as the performance, power consumption, number of interfaces, expansion capability, and programming convenience of the MCU need to be considered. At the same time, it is also necessary to comprehensively consider the specific needs and budget of the system and select the most suitable MCU model.

During the debugging process, it is necessary to pay attention to whether the hardware circuit is connected correctly, whether the components are damaged, whether there are logical errors in the program, etc. At the same time, the system needs to be fully tested, including functional testing, performance testing, stability testing, etc., to ensure the normal operation of the system and meet the design requirements.

System upgrades and maintenance of MCU control units are usually achieved through technical means such as online programming (ISP) or online debugging (ICD). Users can use these technical means to perform program updates, troubleshooting, and performance optimization on the MCU. At the same time, the system needs to be regularly maintained and serviced to extend the service life of the system and maintain its good operating condition.

The sensor module is a key part of the MCU chicken house environment monitoring system. It is used to monitor the environmental parameters in the chicken house in real time, such as temperature, humidity, light intensity, harmful gas concentration, etc., to provide accurate data support for the MCU control unit.

In the chicken house environment monitoring system, commonly used sensor types include temperature sensors (such as DHT11), humidity sensors, light sensors (such as photoresistors), gas sensors (such as MQ-135), etc. These sensors can measure parameters such as temperature, humidity, light intensity and harmful gas concentration in the chicken house.

The working principle of the sensor module is usually to convert the environmental parameters in the chicken house into electrical signals, and then transmit them to the single-chip microcomputer control unit through an analog or digital interface. The single-chip microcomputer control unit then processes and analyzes these signals to achieve monitoring and control of the chicken house environment.

In order to ensure the accuracy and stability of the sensor module, it is necessary to select high-precision and high-stability sensor components, and strictly calibrate and test them. At the same time, in the design and manufacturing process of the sensor module, circuits and components with strong anti-interference ability and high stability need to be used to improve its anti-interference ability and stability.

The sensor module usually communicates with the single-chip microcomputer control unit through an analog or digital interface. Analog interfaces usually use voltage or current signals to transmit data, while digital interfaces use binary codes to transmit data. The microcontroller control unit reads the data transmitted by the sensor module through the interface and processes and analyzes it.

When selecting, factors such as the performance indicators of the sensor module (such as measurement range, accuracy, stability, etc.), interface type (such as analog interface or digital interface), power consumption, size and installation convenience need to be considered. At the same time, it is also necessary to make a comprehensive consideration based on the specific needs and budget of the chicken house environment monitoring system to select the most suitable sensor module model.

The faults that may occur during the use of the sensor module include damage to internal components, poor line connection, loose interface, etc. These faults may cause the sensor module to fail to work properly or transmit incorrect data.

Troubleshooting the sensor module usually requires the use of test tools such as a multimeter to check whether the power supply voltage, output signal, etc. of the sensor are normal. At the same time, it is also necessary to check whether the line connection between the sensor module and the microcontroller control unit is good, whether the interface is loose, etc. If a problem is found, it is necessary to replace the damaged components or repair the line connection in time.

The maintenance and care of the sensor module usually includes regular cleaning of the sensor surface, checking whether the line connection is good, and regular calibration of the sensor. At the same time, it is also necessary to avoid the sensor from being affected by mechanical damage or chemical corrosion to ensure its long-term stable operation.

With the continuous development of technologies such as the Internet of Things and big data, the technical development trend of sensor modules will pay more attention to intelligence, networking and miniaturization. The future sensor module will have higher accuracy, lower power consumption and stronger anti-interference ability. At the same time, it will also support functions such as wireless transmission and remote monitoring to meet the needs of the chicken house environment monitoring system for high-precision, real-time monitoring and remote management.

The actuator module is an important part of the single-chip chicken house environment monitoring system. It is responsible for real-time adjustment of environmental parameters in the chicken house according to the instructions of the single-chip control unit, such as ventilation, heating, cooling, lighting, etc., to ensure that the chicken house environment is in the best state.

The actuator module usually includes ventilation equipment (such as fans, exhaust fans), heating equipment (such as heaters, electric blankets), cooling equipment (such as spray devices, water cooling systems), lighting equipment (such as LED lights, energy-saving lamps), etc. These devices work according to the instructions of the single-chip control unit to achieve precise control of the chicken house environment.

The actuator module communicates with the single-chip control unit through a digital or analog interface. The single-chip control unit sends control instructions to the actuator module through the interface after processing and analyzing the data transmitted by the sensor module. After receiving the instructions, the actuator module drives the corresponding equipment to work.

The accuracy and response speed of the actuator module depend on its design and manufacturing level. A high-precision actuator module can execute the instructions of the single-chip control unit more accurately, and a fast response speed can ensure that the chicken house environment is adjusted in a timely and effective manner. Therefore, when selecting an actuator module, performance indicators such as its accuracy and response speed need to be considered.

Faults that may occur during the use of the actuator module include equipment damage, poor line connection, power failure, etc. These faults may cause the actuator module to fail to work properly or respond to the instructions of the single-chip control unit.

Troubleshooting the actuator module usually requires the use of test tools such as multimeters to check the power supply voltage of the device, whether the line connection is good, and whether the device itself is damaged. At the same time, it is also necessary to check whether the communication interface between the single-chip control unit and the actuator module is working properly. If problems are found, it is necessary to replace the damaged device or repair the line connection in time.

The maintenance and care of the actuator module usually includes regular cleaning of the equipment surface, checking whether the line connection is good, and regular lubrication of mechanical parts. At the same time, it is also necessary to avoid the equipment from being affected by mechanical damage or chemical corrosion. For long-term running equipment, regular inspection and maintenance are also required to ensure its long-term stable operation.

The performance of the actuator module can be evaluated from multiple aspects, including its accuracy, response speed, stability, durability, and energy consumption. In practical applications, the compatibility of the actuator module with the microcontroller control unit and its ability to work with other devices must also be considered.

When selecting, factors such as the performance indicators (such as accuracy, response speed, etc.), power consumption, size, installation method, and compatibility with other devices of the actuator module need to be considered. At the same time, it is also necessary to comprehensively consider the specific needs and budget of the chicken house environment monitoring system and select the most suitable actuator module model.

With the continuous development of technologies such as the Internet of Things and intelligence, actuator modules will pay more attention to intelligence, networking and miniaturization in the future. The actuator modules of the future will have higher precision, faster response speed and stronger adaptability. At the same time, they will also support functions such as remote monitoring and fault diagnosis to meet the needs of the chicken house environment monitoring system for high precision, real-time monitoring and remote management.

The communication module is responsible for transmitting data and control instructions between the single-chip control unit and other devices (such as sensor modules, actuator modules and remote monitoring centers). It is a key component for realizing remote monitoring, data analysis and intelligent control of the chicken house environment monitoring system.

Common communication protocols include Modbus, RS-485, CAN bus, Zigbee, Wi-Fi, etc. These protocols have their own characteristics and are suitable for different application scenarios. For example, Modbus and RS-485 are often used in wired communication, with the advantages of long transmission distance and high stability; while Zigbee and Wi-Fi are suitable for wireless communication, with the characteristics of flexible networking and convenient remote monitoring.

To ensure the stability and reliability of data transmission, communication modules usually use error checking, retransmission mechanism, data encryption and other technologies. In addition, the selection of high-quality communication modules and stable communication protocols is also a key factor. When deploying, it is also necessary to consider the interference factors of the communication environment, such as electromagnetic interference, signal attenuation, etc., and take corresponding anti-interference measures.

The faults that may occur during the use of the communication module include communication interruption, data transmission error, weak or unstable signal, etc. These faults may be caused by hardware failure, software error, incompatible communication protocol or interference from the communication environment.

Troubleshooting the communication module usually requires inspection from multiple aspects such as hardware connection, software configuration, communication protocol and communication environment. Test tools (such as oscilloscopes and network testers) can be used to detect signal quality, communication rate, and packet integrity. At the same time, check whether the firmware version of the communication module is the latest and whether there are any known compatibility issues.

The maintenance and service of the communication module mainly includes regularly checking whether the hardware connection is firm, cleaning the communication interface, updating the firmware version, and monitoring the communication performance. In addition, care should be taken to avoid physical damage or chemical corrosion to the communication module. In harsh communication environments, additional protection measures may be required, such as adding signal amplifiers and using shielded wires.

Many communication modules support remote monitoring and management functions, such as uploading data to a cloud server via Wi-Fi or mobile networks. This allows users to remotely view the data of the chicken house environment monitoring system, receive alarm information, and send control instructions through terminal devices such as mobile phone APP and computers.

When selecting a communication module, factors such as communication distance, communication rate, power consumption, cost, compatibility, and whether remote monitoring needs to be supported need to be considered. In addition, it is necessary to make comprehensive considerations based on the specific needs and deployment environment of the chicken house environment monitoring system to select the most suitable communication module.

Communication modules are usually integrated with other devices through standard interfaces or protocols. For example, connect with sensor modules and actuator modules through RS-485 or CAN bus interfaces; communicate with remote monitoring centers through Wi-Fi or Zigbee protocols. During the integration process, it is necessary to ensure the consistency of communication protocols and the compatibility between devices. At the same time, necessary software configuration and debugging are required to achieve collaborative work between devices.

The development trend of communication modules in the future will pay more attention to low power consumption, high speed, high reliability and intelligence. With the continuous development of Internet of Things technology, communication modules will support more communication protocols and frequency bands to meet the needs of different application scenarios. At the same time, communication modules will also integrate more intelligent functions, such as automatically adjusting the communication rate, optimizing the communication path, etc., to improve communication efficiency and stability.

The power module is responsible for providing a stable and reliable power supply for the microcontroller control unit, sensor module, actuator module, etc., to ensure the normal operation of the entire monitoring system.

Common faults of the power module include unstable output voltage, too high or too low input voltage, severe module heating, and large output noise.

You can judge whether it is working properly by measuring the input voltage and output voltage of the power module. At the same time, observing whether the power module has abnormal heating, noise and other phenomena is also an important basis for judging its working status.

Unstable output voltage may be caused by input voltage fluctuations, load changes, damage to internal components of the power module, etc. In addition, the power module is too close to the noise-sensitive components in the main circuit, which may also cause unstable output voltage.

Too high input voltage may damage the power module. The solution includes ensuring that the input voltage is within the rated voltage range of the power module. If there is interference voltage, a TVS tube or a voltage regulator tube can be connected in parallel at the input end to suppress it.

The serious heating of the power module may be caused by overcurrent of the load, too small load (too low power), too high ambient temperature or poor heat dissipation. In addition, the use of linear power modules may also cause serious heating.

High output noise may interfere with the normal operation of the system. The solutions include keeping the power module away from the noise-sensitive components in the main circuit, connecting a 0.1uF decoupling capacitor to the power input terminal of the noise-sensitive components in the main circuit, and using a multi-channel output power module to replace multiple single-channel output modules to reduce difference frequency interference.

Choosing a suitable power module requires considering factors such as the input voltage range, output voltage and current requirements, power requirements, size and installation method of the system. At the same time, the reliability, stability and service life of the power module also need to be considered.

The power module generally does not require regular maintenance, but its working status should be checked regularly, including measuring the input and output voltages, observing the heating situation, etc. If abnormalities are found, they should be handled in time.

Prolonging the service life of the power module can be achieved by reasonably selecting the load, maintaining a suitable ambient temperature, strengthening heat dissipation, avoiding overcurrent and overvoltage, etc. At the same time, choosing a high-quality power module is also an important factor in extending the service life.

The single-chip control unit realizes logical judgment and instruction issuance through internal logic circuits and instruction sets. Specifically:

Logical judgment:

The single-chip microcomputer contains a logic operation unit, which can perform logical operations on the input data, such as AND, OR, NOT, XOR, etc.

These logic operation units process the input signal according to preset conditions or algorithms to make logical judgments.

For example, in the chicken house environment monitoring system, the single-chip microcomputer can judge whether the current environment is suitable for chicken growth through logical operations based on the temperature, humidity and other data transmitted by the sensor.

Instruction issuance:

After the single-chip microcomputer makes a logical judgment, it will issue corresponding control instructions to other modules (such as actuator modules) according to the judgment results.

These instructions are transmitted to other modules through the output port of the single-chip microcomputer, thereby realizing the adjustment of the chicken house environment.

For example, if the microcontroller determines that the current temperature of the chicken house is too high, it will issue a command to the ventilation equipment to start to lower the temperature.

The chicken house environment monitoring system based on the microcontroller has the following advantages:

Real-time monitoring: The system can monitor the environmental parameters in the chicken house in real time, such as temperature, humidity, light intensity, concentration of harmful gases, etc., to ensure that the chicken house environment is always in a suitable state.

Automated management: Through the microcontroller control unit, the system can realize the automated management of the chicken house environment, automatically adjust the ventilation, heating, cooling, lighting and other equipment according to the real-time monitoring data, and reduce the cost of manual intervention.

Data support: The system can record and store a large amount of historical data to provide data support for the optimization management of the chicken house environment. Through data analysis, the law of changes in the chicken house environment can be found out and a more reasonable breeding strategy can be formulated.

Alarm function: When the environmental parameters are detected to be abnormal, the system will automatically issue an alarm to remind the staff to take timely measures to adjust them to avoid adverse effects on the growth of chickens.

Remote monitoring: Some systems also support the transmission of data to the remote monitoring center via wireless networks, realizing the function of remote viewing and management of the chicken house environment, improving the convenience and efficiency of management.

Economical and practical: Systems based on single-chip microcomputers usually use simple and economical hardware equipment, which reduces the system cost. At the same time, due to the high level of automation and intelligence of the system, it can reduce material waste and labor costs and improve breeding efficiency.

The chicken house environment monitoring system based on single-chip microcomputers is suitable for the following occasions:

Large-scale or small and medium-sized chicken house breeding occasions. The system can monitor key environmental parameters such as temperature, humidity, concentration of harmful gases (such as ammonia, carbon dioxide), and light intensity in the chicken house in real time, and automatically adjust environmental conditions according to the monitoring data, such as controlling exhaust fans, lighting and other equipment to ensure that the chicken house is maintained in the best growth environment. In addition, the system also has an alarm function. When the environmental parameters exceed the preset threshold, an alarm will be issued in time to remind the management personnel to take corresponding measures.

IOT Cloud Platform

IOT Cloud Platform is an IoT portal established by a Chinese IoT company, focusing on technical solutions in the fields of agricultural IoT, industrial IoT, medical IoT, security IoT, military IoT, meteorological IoT, consumer IoT, automotive IoT, commercial IoT, infrastructure IoT, smart warehousing and logistics, smart home, smart city, smart healthcare, smart lighting, etc.

The IoT Cloud Platform blog is a top IoT technology stack, providing technical knowledge on IoT, robotics, artificial intelligence (generative artificial intelligence AIGC), edge computing, AR/VR, cloud computing, quantum computing, blockchain, smart surveillance cameras, drones, RFID tags, gateways, GPS, 3D printing, 4D printing, autonomous driving, etc.