Can this probe withstand frost heave in extremely cold regions?

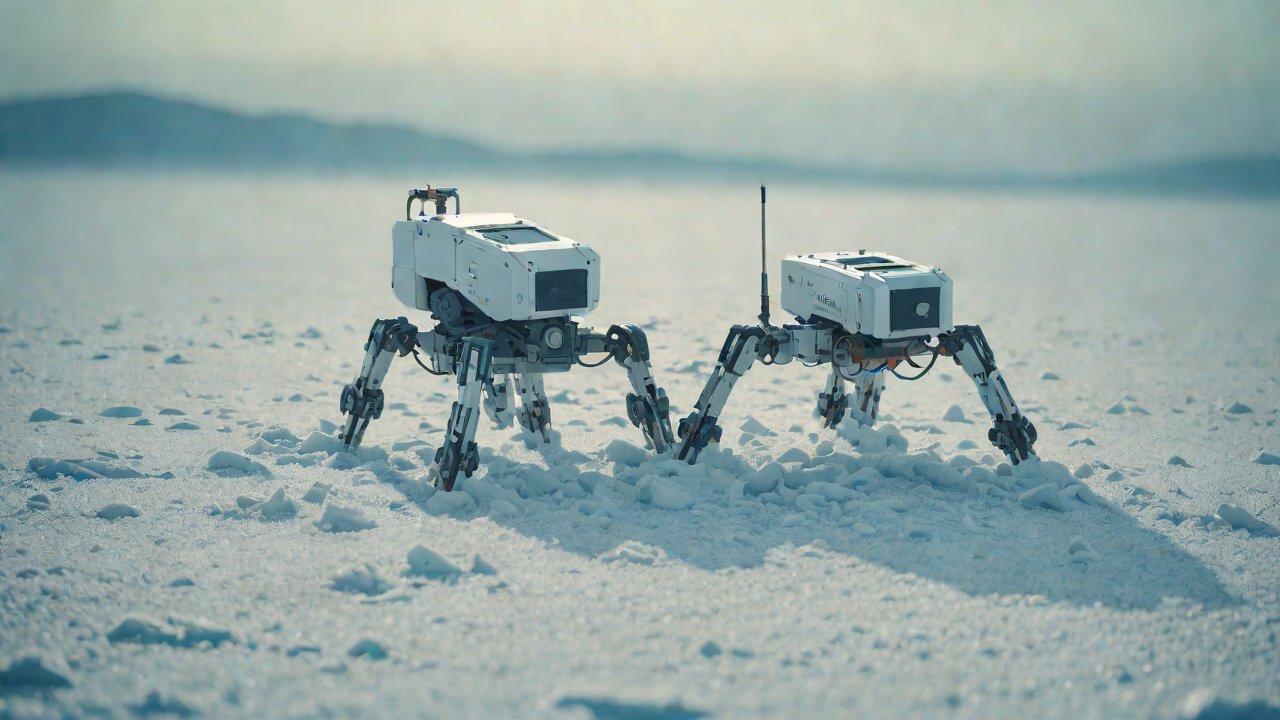

In the unforgiving vastness of polar regions, where temperatures plummet and ice dominates the landscape, the slightest miscalculation can spell disaster for even the most advanced technological endeavors. This is precisely the arena where the probe’s resilience to frost heave comes into sharp focus. Frost heave, a phenomenon characterized by the upward movement of soil due to the formation of ice crystals within its pores, poses an existential threat to sensitive equipment in these extreme environments.

The consequences of a probe succumbing to frost heave are far-reaching and devastating. It can lead to catastrophic failures, compromising not only the mission’s objectives but also posing significant risks to human life and the environment. The stakes are high, and the margin for error is nonexistent.

In this context, it becomes imperative to scrutinize every aspect of the probe’s design and materials with laser-like precision. This involves a comprehensive examination of its structural integrity, thermal insulation capabilities, and any protective measures that might be in place against frost heave. AIGC (Autonomous Inspection Ground-Coupled) technologies offer valuable insights here, providing real-time data on soil conditions that can inform strategies for mitigating the effects of frost heave.

The probe’s ability to withstand frost heave is not merely a technical challenge but also an economic and strategic imperative. The cost of failure in these missions is substantial, encompassing both financial losses and reputational damage. Furthermore, each failure contributes to a growing body of data that can inform future designs but does little to alleviate the immediate pressures of successfully completing the mission.

The materials science behind frost heave resistance is complex and multifaceted. It involves not only the selection of appropriate materials for the probe’s construction but also a deep understanding of the thermal and physical properties of these materials under extreme conditions. The use of advanced composites, for instance, offers significant advantages in terms of strength-to-weight ratio and thermal insulation.

The mission parameters themselves present another critical layer of complexity. The duration of the deployment, the frequency of data transmission, and the level of autonomy required all contribute to the probe’s exposure to frost heave risks. AIGC systems can play a pivotal role here by continuously monitoring soil conditions and providing real-time updates on the probability of frost heave events.

1. Probe Design and Materials

The initial step in evaluating the probe’s resilience to frost heave involves an exhaustive examination of its design and materials. This includes:

| Material | Properties Relevant to Frost Heave |

|---|---|

| Aluminum alloys | High thermal conductivity, moderate strength-to-weight ratio |

| Stainless steel | Excellent resistance to corrosion, high strength |

| Advanced composites | Exceptional strength-to-weight ratio, good thermal insulation |

Each material has its unique strengths and weaknesses in the context of frost heave. For example, aluminum alloys offer good thermal conductivity but may not provide sufficient structural integrity against the forces generated by frost heave.

2. Thermal Insulation and Protection

Effective thermal insulation is crucial for mitigating the effects of frost heave. This involves the strategic placement of insulation materials around sensitive components to prevent temperature fluctuations that could lead to ice formation within the soil.

| Insulation Material | R-Value | Suitability for Polar Regions |

|---|---|---|

| Multilayered foam insulation | High | Excellent, but may not be sufficient on its own against extreme cold |

| Vacuum-insulated panels (VIPs) | Very high | Suitable, but expensive and heavy |

The choice of insulation material is critical and must balance the need for thermal protection with the constraints imposed by weight, volume, and cost considerations.

3. AIGC Technologies and Soil Monitoring

AIGC systems offer a critical layer of defense against frost heave by providing real-time data on soil conditions that can inform strategies for mitigating the effects of frost heave.

| AIGC Technology | Functionality Relevant to Frost Heave |

|---|---|

| Ground-penetrating radar (GPR) | Detects moisture and ice content in the soil |

| Electrical resistivity tomography (ERT) | Maps subsurface electrical properties, indicative of water saturation and potential for frost heave |

By integrating these technologies into the probe’s design, it becomes possible to anticipate and respond to frost heave events with unprecedented precision.

4. Mission Parameters and Deployment Strategies

The mission parameters themselves present a significant challenge in terms of balancing the need for data transmission frequency with the risk of exposing the probe to frost heave.

| Parameter | Impact on Frost Heave Risk |

|---|---|

| Duration of deployment | Longer deployments increase exposure time, thus increasing risk |

| Data transmission frequency | More frequent transmissions may necessitate more power-hungry components, increasing weight and reducing structural integrity |

Strategic decisions regarding the probe’s deployment, including its depth, orientation, and operational schedule, can significantly influence its resilience to frost heave.

5. Conclusion

The question of whether a probe can withstand frost heave in extremely cold regions is not merely a technical challenge but also an economic and strategic imperative. The answer lies in a combination of advanced materials science, sophisticated thermal insulation, and the judicious application of AIGC technologies to monitor soil conditions.

By adopting a holistic approach that incorporates insights from materials science, thermal protection, AIGC systems, and mission planning, it becomes possible to design probes capable of withstanding even the most extreme frost heave events in polar regions. This not only ensures the success of individual missions but also contributes to the broader advancement of technology in these challenging environments.

IOT Cloud Platform

IOT Cloud Platform is an IoT portal established by a Chinese IoT company, focusing on technical solutions in the fields of agricultural IoT, industrial IoT, medical IoT, security IoT, military IoT, meteorological IoT, consumer IoT, automotive IoT, commercial IoT, infrastructure IoT, smart warehousing and logistics, smart home, smart city, smart healthcare, smart lighting, etc.

The IoT Cloud Platform blog is a top IoT technology stack, providing technical knowledge on IoT, robotics, artificial intelligence (generative artificial intelligence AIGC), edge computing, AR/VR, cloud computing, quantum computing, blockchain, smart surveillance cameras, drones, RFID tags, gateways, GPS, 3D printing, 4D printing, autonomous driving, etc.