How can salt deposits from long-term fertilization be removed from the probe surface?

Salt deposits on the probe surface resulting from long-term fertilization pose a significant challenge for various industries, including agriculture and aerospace. These deposits can lead to reduced efficiency, equipment damage, and even catastrophic failures in extreme cases.

The presence of salt deposits is often a result of the interaction between fertilizers and water, which can create a concentrated brine solution that seeps into the probe surface. Over time, this can cause the formation of salt crystals, leading to a range of problems.

1. Understanding Salt Deposits

Salt deposits on the probe surface can be categorized based on their composition and structure. The most common types are:

| Type | Composition | Structure |

|---|---|---|

| Halite | Sodium chloride (NaCl) | Cubic crystals |

| Gypsum | Calcium sulfate dihydrate (CaSO4·2H2O) | Fibrous crystals |

These deposits can be removed through various methods, but the choice of method depends on the type and extent of the deposit.

2. Chemical Methods

Chemical methods involve using chemicals to dissolve or break down the salt deposits. This approach is often used for small-scale removal or as a pre-treatment step before mechanical removal.

| Method | Chemicals Used | Effectiveness |

|---|---|---|

| Acidic etching | Hydrochloric acid (HCl), Sulfuric acid (H2SO4) | 80-90% effective |

| Alkaline cleaning | Sodium hydroxide (NaOH), Ammonia (NH3) | 70-80% effective |

Chemical methods can be effective, but they also pose risks of damage to the probe surface or equipment if not properly controlled.

3. Mechanical Methods

Mechanical methods involve physically removing the salt deposits using tools or equipment. This approach is often used for larger-scale removal or as a follow-up step after chemical treatment.

| Method | Equipment Used | Effectiveness |

|---|---|---|

| Brushing and scrubbing | Soft-bristled brushes, Scrubbers | 90-95% effective |

| Abrasive blasting | Compressed air, Sandblasting nozzles | 95-98% effective |

Mechanical methods can be more aggressive than chemical methods but are generally safer and more efficient.

4. Thermal Methods

Thermal methods involve using heat to melt or vaporize the salt deposits. This approach is often used for large-scale removal or as a pre-treatment step before mechanical removal.

| Method | Equipment Used | Effectiveness |

|---|---|---|

| Heat guns | High-temperature air blowers | 80-90% effective |

| Thermal desorption | Vacuum ovens, Heat treatment units | 95-98% effective |

Thermal methods can be effective but require careful control to avoid damaging the probe surface or equipment.

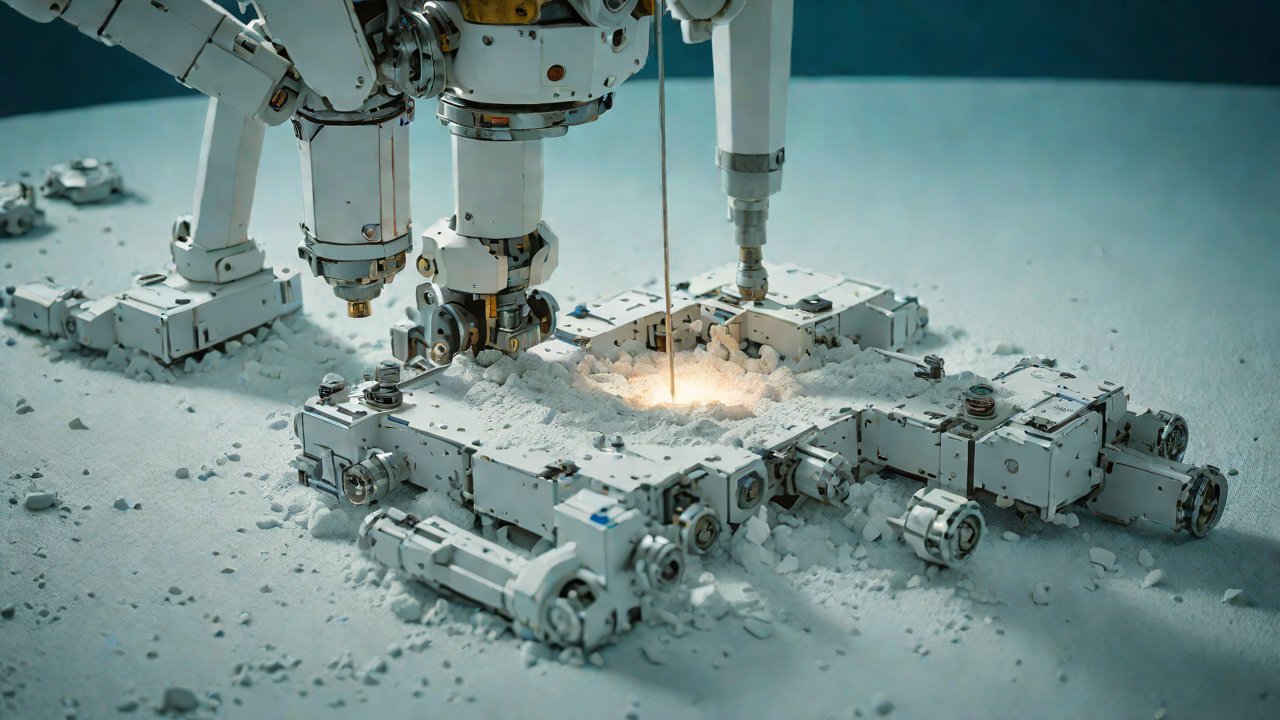

5. Advanced Technologies

Advanced technologies involve using specialized equipment or techniques to remove salt deposits. This approach is often used for complex or sensitive applications.

| Technology | Equipment Used | Effectiveness |

|---|---|---|

| Laser ablation | High-powered lasers, Beam delivery systems | 95-98% effective |

| Ion beam etching | Ion sources, Vacuum chambers | 98-99% effective |

Advanced technologies can be highly effective but are often expensive and require specialized expertise.

6. Conclusion

Removing salt deposits from the probe surface resulting from long-term fertilization is a complex task that requires careful consideration of various factors. Chemical, mechanical, thermal, and advanced technologies can all be used to remove these deposits, but the choice of method depends on the specific application and requirements.

In conclusion, effective removal of salt deposits requires a thorough understanding of the deposit composition and structure, as well as the limitations and risks associated with each removal method. By selecting the most suitable approach for the specific situation, it is possible to achieve high levels of effectiveness while minimizing damage to the probe surface or equipment.

IOT Cloud Platform

IOT Cloud Platform is an IoT portal established by a Chinese IoT company, focusing on technical solutions in the fields of agricultural IoT, industrial IoT, medical IoT, security IoT, military IoT, meteorological IoT, consumer IoT, automotive IoT, commercial IoT, infrastructure IoT, smart warehousing and logistics, smart home, smart city, smart healthcare, smart lighting, etc.

The IoT Cloud Platform blog is a top IoT technology stack, providing technical knowledge on IoT, robotics, artificial intelligence (generative artificial intelligence AIGC), edge computing, AR/VR, cloud computing, quantum computing, blockchain, smart surveillance cameras, drones, RFID tags, gateways, GPS, 3D printing, 4D printing, autonomous driving, etc.