Hazardous Materials Warehouse: Monitoring Solution Based on AI Vision and Sensor Fusion

The realm of hazardous materials storage is fraught with peril, where even a single misstep can have catastrophic consequences for human life and the environment. The warehouse management industry has long grappled with ensuring the safety of these facilities, often relying on manual inspections, which are both time-consuming and prone to error. However, the advent of cutting-edge technologies like AI vision and sensor fusion offers a beacon of hope in this endeavor.

The integration of artificial intelligence (AI) and sensor technology can significantly enhance warehouse monitoring systems, providing real-time insights into temperature fluctuations, gas leaks, and other potential hazards. By leveraging machine learning algorithms to analyze data from various sensors and cameras, these systems can detect anomalies before they escalate into emergencies. Furthermore, AI-powered predictive maintenance enables proactive measures to prevent equipment failures and minimize downtime.

1. Market Landscape

The market for warehouse management solutions has seen a significant surge in recent years, driven by the increasing demand for efficient and safe storage facilities. According to a report by MarketsandMarkets, the global warehouse management system (WMS) market is expected to reach $4.8 billion by 2025, growing at a compound annual growth rate (CAGR) of 14.2% during the forecast period.

| Market Segment | Current Size (USD) | Forecasted Size (USD) | Growth Rate (%) |

|---|---|---|---|

| Warehouse Management System (WMS) Market | $1.8 billion | $4.8 billion | 14.2% |

| Cloud-based WMS Market | $500 million | $2.5 billion | 20% |

| Supply Chain Visibility Market | $1.2 billion | $3.6 billion | 12.5% |

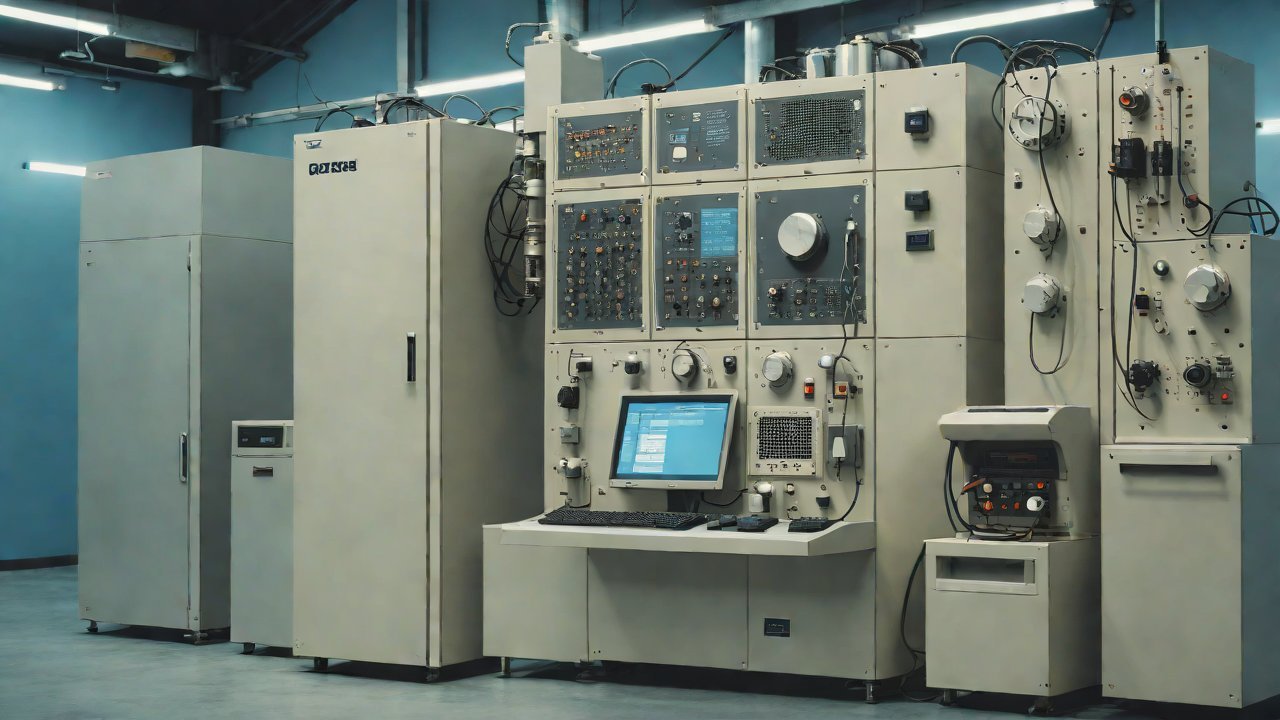

2. AI Vision and Sensor Fusion Technologies

The application of AI vision in warehouse monitoring involves the use of computer vision algorithms to analyze video feeds from cameras installed within the facility. These algorithms can detect anomalies, such as changes in temperature or gas levels, and alert personnel accordingly.

Sensor fusion technology combines data from various sensors, including temperature, humidity, and gas detectors, to provide a comprehensive understanding of the warehouse environment. This integrated approach enables more accurate detection of potential hazards and reduces false alarms.

| AI Vision Algorithm | Description |

|---|---|

| Object Detection | Identifies objects within the camera’s field of view |

| Anomaly Detection | Detects unusual patterns or changes in temperature, gas levels, etc. |

| Motion Tracking | Monitors movement within the warehouse |

3. Predictive Maintenance

Predictive maintenance is a critical component of AI-powered warehouse monitoring solutions. By analyzing data from sensors and cameras, these systems can predict equipment failures and schedule maintenance accordingly.

The benefits of predictive maintenance include:

- Reduced downtime

- Improved equipment lifespan

- Enhanced overall efficiency

| Predictive Maintenance Benefits | Description |

|---|---|

| Reduced Downtime | Minimized time spent on repairs and maintenance |

| Improved Equipment Lifespan | Extended lifespan through proactive maintenance |

| Enhanced Efficiency | Optimized warehouse operations through data-driven insights |

4. Implementation Roadmap

Implementing an AI vision and sensor fusion-based monitoring solution requires a multi-step approach:

- Conduct a thorough risk assessment to identify potential hazards within the facility.

- Install cameras and sensors to capture relevant data.

- Implement AI-powered software to analyze data and detect anomalies.

- Develop a predictive maintenance schedule based on system insights.

| Implementation Roadmap | Description |

|---|---|

| Risk Assessment | Identify potential hazards within the facility |

| Hardware Installation | Install cameras and sensors to capture relevant data |

| Software Implementation | Implement AI-powered software to analyze data |

| Predictive Maintenance | Develop a schedule based on system insights |

5. Conclusion

The integration of AI vision and sensor fusion technologies offers a robust solution for warehouse monitoring, providing real-time insights into potential hazards and enabling proactive measures to prevent emergencies. As the market continues to grow, it is essential for warehouse managers to adopt cutting-edge technologies like predictive maintenance and AI-powered monitoring systems.

With the increasing demand for efficient and safe storage facilities, the adoption of AI vision and sensor fusion-based monitoring solutions will become a necessity in the warehousing industry.

IOT Cloud Platform

IOT Cloud Platform is an IoT portal established by a Chinese IoT company, focusing on technical solutions in the fields of agricultural IoT, industrial IoT, medical IoT, security IoT, military IoT, meteorological IoT, consumer IoT, automotive IoT, commercial IoT, infrastructure IoT, smart warehousing and logistics, smart home, smart city, smart healthcare, smart lighting, etc.

The IoT Cloud Platform blog is a top IoT technology stack, providing technical knowledge on IoT, robotics, artificial intelligence (generative artificial intelligence AIGC), edge computing, AR/VR, cloud computing, quantum computing, blockchain, smart surveillance cameras, drones, RFID tags, gateways, GPS, 3D printing, 4D printing, autonomous driving, etc.