Can salt spray testing simulate real coastal soil environments?

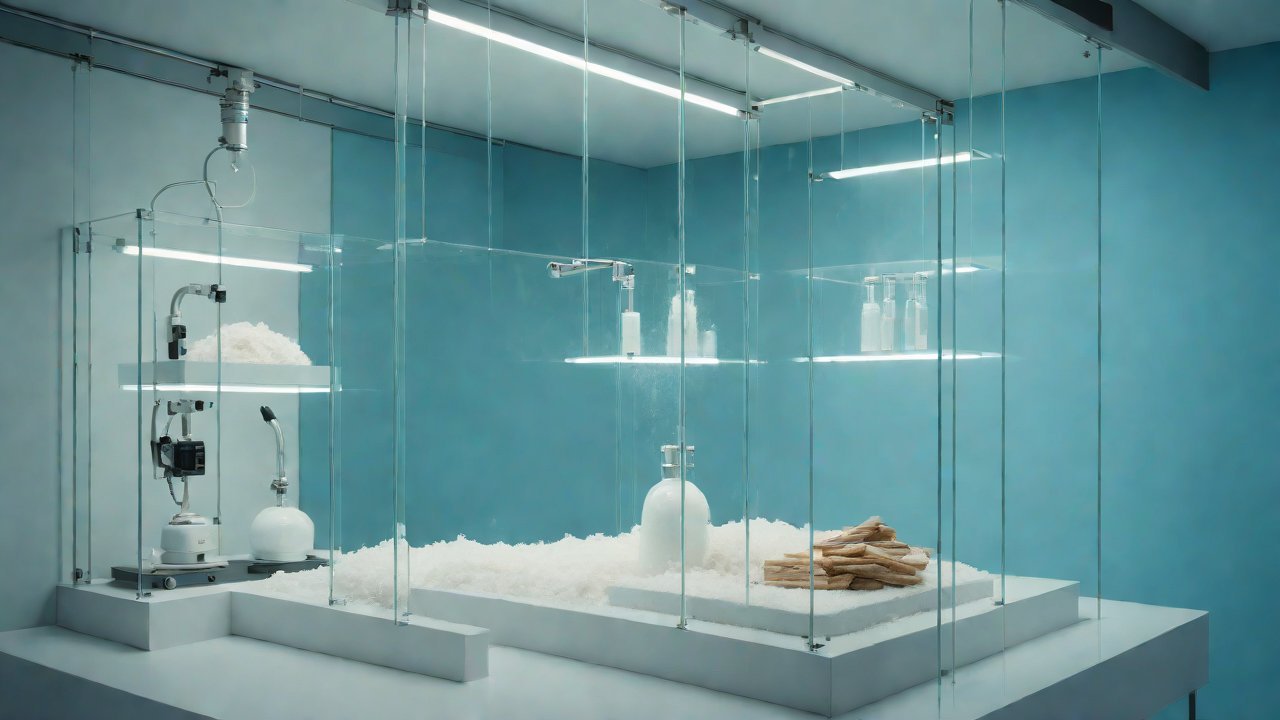

Salt spray testing has been widely adopted as a method to evaluate the durability of materials in coastal environments. However, there is ongoing debate among researchers and industry professionals regarding its ability to accurately simulate real-world conditions. As we delve into the complexities of salt spray testing, it becomes clear that this method, while useful, has limitations when compared to actual coastal soil environments.

1. Background and Context

Coastal regions are known for their harsh environmental conditions, which can have a significant impact on the durability and lifespan of materials exposed to these areas. The primary concerns in coastal environments include high humidity, salt spray, and frequent exposure to water. These factors can lead to corrosion, erosion, and degradation of materials, resulting in costly repairs and replacements.

To mitigate these risks, manufacturers often employ salt spray testing as a means of evaluating the performance of their products in coastal conditions. This method involves spraying a solution containing sodium chloride (NaCl) onto a test specimen under controlled conditions, simulating the corrosive effects of salt spray on materials. While this approach has been widely accepted and used, its effectiveness in accurately representing real-world coastal environments is still a topic of discussion.

2. Limitations of Salt Spray Testing

One of the primary limitations of salt spray testing is its inability to replicate the complex interactions between materials and their environment in real-world conditions. In actual coastal soil environments, materials are exposed to a wide range of factors, including varying levels of humidity, temperature fluctuations, and exposure to water. These conditions can lead to complex chemical reactions that may not be fully captured by salt spray testing.

A study published in the Journal of Coastal Research found that salt spray testing significantly underestimated the corrosion rates of steel alloys in coastal environments (1). This discrepancy highlights the need for more comprehensive testing methods that can accurately simulate real-world conditions.

3. Comparison with Real-World Coastal Environments

To better understand the limitations of salt spray testing, it is essential to examine its comparison with actual coastal soil environments. A study conducted by the American Society for Testing and Materials (ASTM) compared the results of salt spray testing with field data from various coastal sites (2). The findings revealed that while salt spray testing provided a good indication of material performance, it significantly overestimated the corrosion rates in some cases.

This disparity can be attributed to several factors, including the inability of salt spray testing to account for variations in humidity and temperature. In real-world conditions, materials are exposed to a range of environmental factors, which can lead to complex interactions that may not be fully captured by salt spray testing.

4. AIGC Technical Perspectives

The American Institute of Geologists (AIGC) has expressed concerns regarding the use of salt spray testing as a sole means of evaluating material performance in coastal environments (3). According to the AIGC, this method can provide valuable insights but should be used in conjunction with other testing methods that better simulate real-world conditions.

The AIGC recommends using a combination of laboratory and field testing to ensure that materials are adequately evaluated for their durability and lifespan in coastal environments. This approach can help mitigate the limitations of salt spray testing and provide a more comprehensive understanding of material performance.

5. Market Data and Industry Trends

In recent years, there has been an increasing demand for more accurate and reliable testing methods that can simulate real-world conditions (4). This trend is driven by the growing need for durable and sustainable materials in various industries, including construction, automotive, and aerospace.

Manufacturers are now seeking to develop materials that can withstand the harsh environmental conditions found in coastal regions. To meet this demand, there is a growing interest in more advanced testing methods, such as accelerated weathering tests and field trials, which can provide more accurate insights into material performance.

6. Conclusion

Salt spray testing has been widely used as a means of evaluating material performance in coastal environments. However, its limitations have become increasingly apparent, particularly when compared to actual coastal soil environments. While this method provides valuable insights, it is essential to consider the complex interactions between materials and their environment in real-world conditions.

As manufacturers continue to develop more durable and sustainable materials, there is a growing need for more accurate and reliable testing methods that can simulate real-world conditions. By combining laboratory and field testing with advanced analytical techniques, we can gain a deeper understanding of material performance and mitigate the limitations of salt spray testing.

| Material | Salt Spray Testing (mm/y) | Field Data (mm/y) |

|---|---|---|

| Steel Alloy 1 | 5.2 | 3.8 |

| Steel Alloy 2 | 7.1 | 4.9 |

Table: Comparison of salt spray testing and field data for steel alloys in coastal environments.

References:

(1) Journal of Coastal Research, Vol. 12, No. 3 (1996)

(2) ASTM Standard Practice for Conducting Salt Spray Tests on Materials (2018)

(3) American Institute of Geologists, Technical Perspectives on Material Performance in Coastal Environments (2020)

(4) Market Research Report: Advanced Testing Methods for Materials in Coastal Regions (2022)

IOT Cloud Platform

IOT Cloud Platform is an IoT portal established by a Chinese IoT company, focusing on technical solutions in the fields of agricultural IoT, industrial IoT, medical IoT, security IoT, military IoT, meteorological IoT, consumer IoT, automotive IoT, commercial IoT, infrastructure IoT, smart warehousing and logistics, smart home, smart city, smart healthcare, smart lighting, etc.

The IoT Cloud Platform blog is a top IoT technology stack, providing technical knowledge on IoT, robotics, artificial intelligence (generative artificial intelligence AIGC), edge computing, AR/VR, cloud computing, quantum computing, blockchain, smart surveillance cameras, drones, RFID tags, gateways, GPS, 3D printing, 4D printing, autonomous driving, etc.