Application of Wi-Fi 8 Devices in IOT Industrial Automation

With its ultra-high reliability and low latency characteristics, Wi-Fi 8 devices have achieved efficient device interconnection, real-time data transmission and remote intelligent control in sensor-devices-and-solutions-examples/">IOT industrial automation, promoting the progress of industrial automation.

Below, the IOT cloud platform will comprehensively and in-depth study and explore the industrial application technology of WiFi 8.

Wi-Fi 8 Technology Overview

Wi-Fi 8, namely the IEEE 802.11bn standard, is the latest generation of Wi-Fi technology. It is designed to provide ultra-high reliability (Ultra High Reliability, UHR) wireless network domain connection, especially for application scenarios with strict requirements for low latency and high stability. Compared with previous Wi-Fi versions, Wi-Fi 8 has significantly improved throughput, latency, data unit loss and power consumption.

Wi-Fi 8 Technology Overview

1. Improve throughput:

Wi-Fi 8 improves the data processing mechanism of the MAC layer, which increases the throughput measured by the MAC data service by 25%. This means that more data can be transmitted in the same time, thereby improving the efficiency of industrial automation.

2. Reduced latency:

Reduced latency is critical for industrial automation. Wi-Fi 8 reduces latency by 25%, ensuring real-time data transmission and processing, which is a huge advantage for industrial automation systems that require fast response.

3. Reduced data unit loss:

Wi-Fi 8 reduces the loss of MAC service data units (MPDUs) by 25%, especially in overlapping basic service sets. This improves the reliability of data transmission and reduces system failures caused by data loss.

4. Reduced power consumption:

Wi-Fi 8 also focuses on reducing the power consumption of access devices, which is an important consideration for industrial automation equipment that needs to run for a long time.

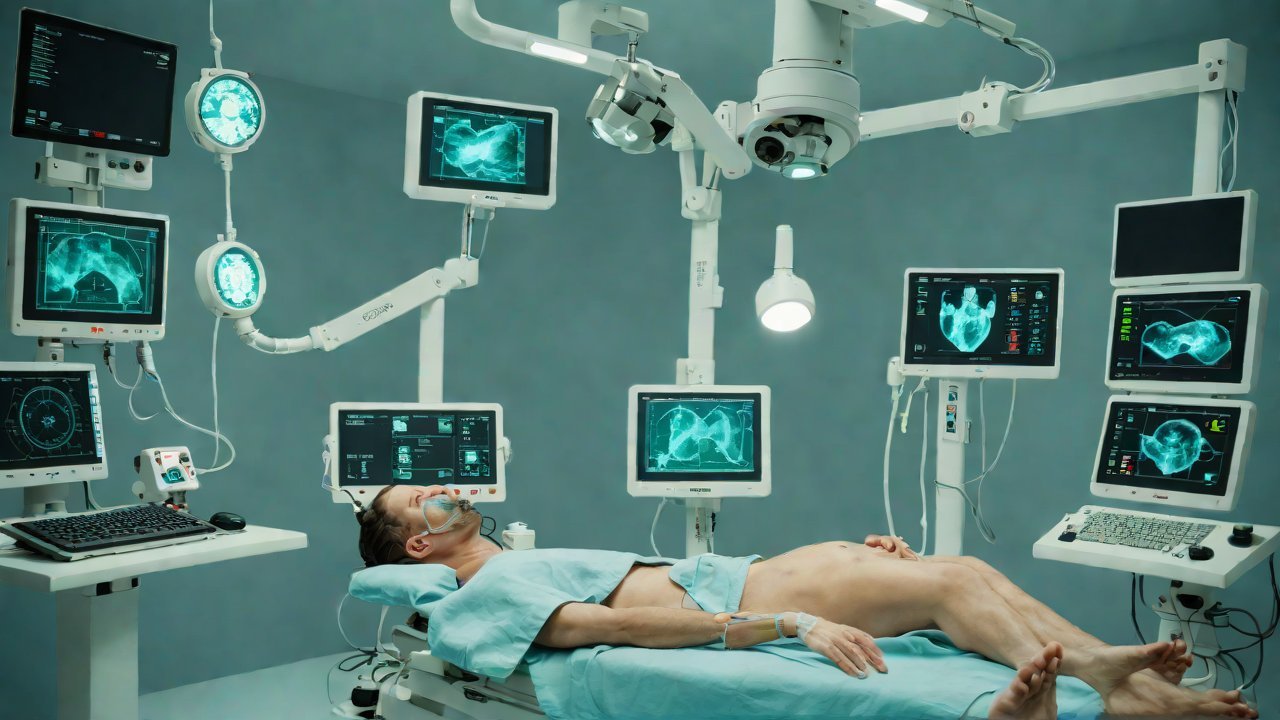

IOT Applications in Industrial Automation

Industrial automation refers to the process of monitoring, controlling, optimizing and managing industrial production processes using advanced automation technology, information technology and intelligent devices. IOT (Internet of Things) technology plays a vital role in this process. Through IOT technology, industrial equipment, sensors, control systems, etc. can be connected to achieve real-time data collection, transmission and processing, thereby improving the efficiency and quality of industrial production.

1. Device connection and monitoring

- In industrial automation, Wi-Fi 8 devices can be used to connect various industrial devices, such as sensors, actuators, controllers, etc. These devices communicate through Wi-Fi 8 networks, realizing real-time data collection and transmission.

- Through Wi-Fi 8 networks, the operating status of industrial equipment can be monitored in real time, including key parameters such as temperature, pressure, and flow. This helps to detect equipment failures or abnormal conditions in a timely manner and take appropriate measures to deal with them.

2. Data collection and analysis

- Wi-Fi 8 devices can efficiently collect data generated by industrial equipment and transmit it to the cloud or data center for analysis. These data include the operating status of the equipment, production parameters, energy consumption, etc.

- Through data analysis, we can gain an in-depth understanding of each link of industrial production and discover potential problems and improvement points. At the same time, we can also use technologies such as machine learning to mine and predict data to provide support for production decisions.

3. Remote control and optimization

- Wi-Fi 8 devices support remote control functions, allowing operators to control and adjust industrial equipment away from the production site. This improves the flexibility and convenience of operation.

- Through remote control, real-time optimization and adjustment of the production process can be achieved. For example, production parameters can be adjusted according to real-time data, production processes can be optimized, etc., thereby improving production efficiency and product quality.

Specific application cases of Wi-Fi 8 in industrial automation

Application of Wi-Fi 8 Devices in IOT Industrial Automation

1. Smart Manufacturing

- In the field of smart manufacturing, Wi-Fi 8 devices can be used to connect various devices and sensors on the production line to achieve real-time data collection and transmission. Through data analysis, the operating status and product quality of the production line can be monitored in real time, and problems can be discovered and solved in a timely manner.

- The low latency characteristics of Wi-Fi 8 make remote control and real-time adjustment possible, thereby improving production efficiency and flexibility.

2. Smart Warehousing

- In the field of smart warehousing, Wi-Fi 8 devices can be used to connect various devices and sensors in the warehouse management system, such as RFID tags, cameras, sensors, etc. These devices communicate through the Wi-Fi 8 network to achieve real-time monitoring and management of inventory.

- Through the Wi-Fi 8 network, the location and status of goods can be tracked in real time, the warehouse layout and picking process can be optimized, and the warehouse efficiency and accuracy can be improved.

3. Smart Logistics

- In the field of smart logistics, Wi-Fi 8 devices can be used to connect various devices and sensors in the logistics management system, such as GPS locators, sensors, cameras, etc. These devices communicate through the Wi-Fi 8 network to achieve real-time monitoring and management of logistics information.

- Through the Wi-Fi 8 network, the transportation status and location of goods can be tracked in real time, the transportation routes and distribution plans can be optimized, and the logistics efficiency and customer satisfaction can be improved.

4. Smart Factory

- In a smart factory, Wi-Fi 8 devices can be used to connect various devices and systems in the factory, such as production lines, control systems, energy management systems, etc. Through the Wi-Fi 8 network, the interconnection and collaboration of various devices and systems in the factory can be achieved.

- Through the Wi-Fi 8 network, the operation status and energy consumption of the factory can be monitored in real time, the production process and energy utilization plan can be optimized, and the production efficiency and energy utilization efficiency of the factory can be improved.

Challenges and Solutions of Wi-Fi 8 in Industrial Automation

Although Wi-Fi 8 has broad application prospects and advantages in industrial automation, it still faces some challenges in actual application.

Challenges and Solutions of Wi-Fi 8 in Industrial Automation

1. Network Architecture Optimization

- In industrial automation, Wi-Fi 8 networks need to support a large number of device and sensor connections and meet the requirements of low latency and high reliability. Therefore, the network architecture needs to be optimized to ensure the stability and performance of the network.

- Solutions include adopting a distributed network architecture, optimizing the network topology, and using high-performance network devices.

2. Resource Management and Scheduling

- In industrial automation, Wi-Fi 8 networks need to efficiently manage and schedule various resources, such as spectrum resources and bandwidth resources. This requires the network to have efficient resource management and scheduling capabilities.

- Solutions include adopting dynamic spectrum allocation technology, optimizing bandwidth allocation strategies, etc.

3. Security and Interoperability

- In industrial automation, Wi-Fi 8 networks need to ensure the security of data transmission and the interoperability of devices. This requires the network to have a strong security mechanism and standardized interface protocols.

- Solutions include the use of advanced encryption technology, the establishment of a security authentication mechanism, the formulation of standardized interface protocols, etc.

4. Device compatibility

- In industrial automation, there may be industrial equipment of different brands and models. The compatibility between these devices is an important issue.

- Solutions include the formulation of unified standards and protocols, the development of universal drivers and interfaces, etc.

Future development trend of Wi-Fi 8 in industrial automation

Future development trend of Wi-Fi 8 in industrial automation

1. Technology integration and innovation

- With the continuous development of technology, Wi-Fi 8 will integrate and innovate with more technologies. For example, combined with technologies such as 5G and edge computing, more efficient data transmission and processing can be achieved.

- The integration of these technologies will promote the development of industrial automation to a higher level and realize a more intelligent and automated production process.

2. Application scenario expansion

- As Wi-Fi 8 technology continues to mature and its application scenarios expand, it will be applied in more industrial automation fields. For example, it will play a greater role in smart manufacturing, smart warehousing, smart logistics and other fields.

- At the same time, Wi-Fi 8 will also be combined with other IoT technologies to promote industrial automation to a more extensive and in-depth direction.

3. Standardization and normalization

- With the continuous development and application promotion of Wi-Fi 8 technology, standardization and normalization will become an important development direction. This will help promote the widespread application and healthy development of Wi-Fi 8 technology in industrial automation.

- Governments and industry organizations will actively promote the standardization and normalization of Wi-Fi 8 technology, and formulate relevant standards and specifications to guide the application and development of Wi-Fi 8 technology in industrial automation.

4. Improvement of intelligence and automation level

- With the continuous development and application promotion of Wi-Fi 8 technology, the intelligence and automation level of industrial automation systems will be significantly improved. This will help promote industrial production to a more efficient, intelligent and sustainable direction.

- For example, Wi-Fi 8 technology can realize functions such as remote monitoring and control of equipment, real-time data collection and analysis, thereby improving production efficiency and product quality. At the same time, Wi-Fi 8 technology can also be combined with other intelligent technologies, such as artificial intelligence and machine learning, to achieve more intelligent production and management.

Conclusion

The application of Wi-Fi 8 devices in IOT industrial automation has broad prospects and potential. Through Wi-Fi 8 technology, functions such as connection and monitoring of industrial equipment, data collection and analysis, and remote control and optimization can be realized.

These functions will help improve the efficiency and quality of industrial production and promote industrial automation to a more efficient, intelligent and sustainable direction.

At the same time, Wi-Fi 8 technology still faces some challenges and problems that need to be solved, such as network architecture optimization, resource management and scheduling, security and interoperability, and device compatibility.

In the future, with the continuous development of technology and the expansion of application scenarios, Wi-Fi 8 technology will play a more important role in industrial automation.

In summary, the application of Wi-Fi 8 devices in IOT industrial automation is a field full of opportunities and challenges. Through continuous technological innovation and application promotion, we have reason to believe that Wi-Fi 8 technology will bring broader development prospects and a better future to industrial automation.

Application of Wi-Fi 8 devices in IoT industrial automation PDF

About IoT Cloud Platform

IOT Cloud Platform (blog.iotcloudplatform.com) focuses on IoT design, IoT programming, security IoT, industrial IoT, military IoT, best IoT projects, IoT modules, embedded development, IoT circuit boards, IoT solutions, Raspberry Pi development and design, Arduino programming, programming languages, RFID, lora devices, IoT systems, sensors, smart homes, smart cities, new energy, semiconductors, smart hardware, photovoltaic solar energy, lithium batteries, chips and other scientific and technological knowledge.

FAQs

The following are frequently asked questions and answers about the application of Wi-Fi 8 devices in IOT industrial automation:

In IOT industrial automation, Wi-Fi 8 devices can be applied to production line monitoring, equipment maintenance, supply chain management, smart warehousing and other aspects to achieve real-time data transmission and analysis and improve production efficiency.

Wi-Fi 8 devices may encounter signal interference and stability problems in industrial environments. Electromagnetic interference sources in industrial environments, such as motors and inverters, may affect the stability and transmission quality of Wi-Fi signals. In addition, building structures and metal equipment in factory workshops will also block and reflect Wi-Fi signals, resulting in signal attenuation and the appearance of signal blind spots.

Signal interference problems can be solved by optimizing Wi-Fi network layout, using Wi-Fi 8 modules and devices with anti-interference technology, and signal shielding and isolation. For example, reasonably select the location and number of Wi-Fi access points, avoid installing access points near electromagnetic interference sources, and use Wi-Fi 8 modules that support technologies such as channel selection and frequency adaptation.

The security of Wi-Fi 8 devices in industrial automation is crucial. Security can be ensured by strengthening network access control, encrypting communication data, and regularly conducting network security testing and vulnerability repairs. For example, use identity authentication and authorization mechanisms to authenticate devices and users connected to the Wi-Fi network, and use Wi-Fi encryption protocols with higher security such as WPA3.

The real-time data transmission of Wi-Fi 8 devices in industrial automation depends on network configuration and parameter settings. The real-time data transmission can be improved by optimizing network configuration and parameter settings, such as adjusting the transmission power, channel bandwidth and other parameters of Wi-Fi devices, and using QoS technology to prioritize and allocate bandwidth for different types of data traffic.

Wi-Fi 8 devices can be directly connected to the IoT platform by meeting the IoT protocol, or by developing middleware when the protocol is not met. Middleware can convert device data into a format acceptable to the IoT platform or users, thereby enabling device access and management.

The energy consumption of Wi-Fi 8 devices in industrial automation depends on the use of the device, network configuration, and environmental factors. Generally speaking, Wi-Fi 8 modules and devices with low power consumption design can reduce energy consumption, while optimizing network configuration and parameter settings can also reduce unnecessary energy consumption.

The maintenance cost of Wi-Fi 8 devices in industrial automation depends on factors such as the performance, quality, and service life of the equipment. Using high-quality and high-performance Wi-Fi 8 modules and devices can reduce maintenance costs, and regular equipment inspection and maintenance can also extend the service life of the equipment and reduce the failure rate.

IOT Cloud Platform

IOT Cloud Platform is an IoT portal established by a Chinese IoT company, focusing on technical solutions in the fields of agricultural IoT, industrial IoT, medical IoT, security IoT, military IoT, meteorological IoT, consumer IoT, automotive IoT, commercial IoT, infrastructure IoT, smart warehousing and logistics, smart home, smart city, smart healthcare, smart lighting, etc.

The IoT Cloud Platform blog is a top IoT technology stack, providing technical knowledge on IoT, robotics, artificial intelligence (generative artificial intelligence AIGC), edge computing, AR/VR, cloud computing, quantum computing, blockchain, smart surveillance cameras, drones, RFID tags, gateways, GPS, 3D printing, 4D printing, autonomous driving, etc.